Making your own PCB boards for DIY electronics projects is not difficult. Doing so as a DIY project is extremely handy and allows almost anyone to custom design one-off, or small batch circuit layouts relatively quickly and cheaply, without the need for the volumes or costs involved in using the services of professional circuit board manufacturers. With care, DIY PCB project results are usually of extremely high quality and are very satisfying. Even more interest can be added to projects when printed circuit boards are combined with CNC cutter designs for shaping of the circuit boards.

There are various different methods for making PCB boards. Each method has various pros and cons, with most considerations being linked to cost, quality of finished product, accuracy required for fine circuits and availability of chemicals and materials.

Here we describe the UV exposure method for transfer of circuit layout image to a pre-sensitized Copper coated PCB blank, followed by etching with Ferric Chloride. The technique is accurate, convenient and provides a high quality etching.

Basic Outline of Steps Required

The UV exposure and etching method requires 6 main steps:

- Design and print the circuit layout onto transparency

- Transfer the circuit design onto a Copper coated PCB blank using UV light exposure

- Develop the exposed image using Sodium Hydroxide

- Etch away Copper between the required circuit tracks and contacts

- Drill holes in the PCB for placement of components (for through-hole PCB designs)

- Screen print and protect the PCB

Required Materials

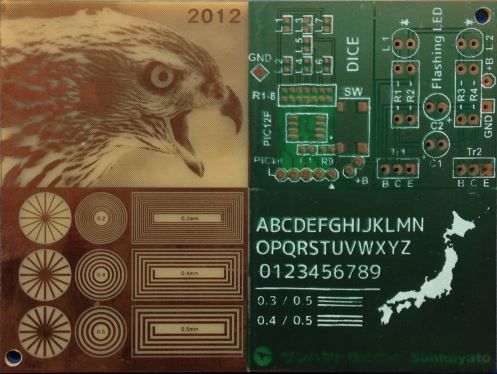

In the past, perhaps the biggest hindrance in using the UV exposure method was perhaps the availability of the required UV sensitized PCB blanks. However, these days, the copper coated PCB blanks and all other chemicals and materials are readily available online or from any good chemical or electronics supply outlet. Our preferred brand and supplier for many electronics and circuit board materials, from Japan is Sunhayato.

- (Optional) Circuit Board Design Software to produce layout design

- UV sensitive PCB board Blanks

- UV light source (UV lamp, tungsten element spot light, or in a pinch, bright sunshine)

- Personal Protection Equipment (chemical resistant gloves, eye goggles, chemical resistant apron, etc)

- Sodium Hydroxide Solution for developing – ie: highly corrosive!

- Ferric Chloride (for Copper etching) – ie: also highly corrosive and toxic!

- Ample running wash water

- Shallow plastic trays (x2) nb: Do not use metal!

- Wood or plastic tongs

Computer Design Software Available

Computer circuit and PCB design packages with Opensource GPL, free or sponsored licenses will more than likely satisfy the needs of many DIY electronics hobbyists. Some examples include: Fritzing, PCB Artist, DipTrace, XCircuit and gEDA to name a few. These are listed without order or preference and offer differing features, capability and quality.

Many commercial design packages are also available, but can be pricy if you are just messing with home DIY projects. Such an option that we like however is Eagle PCB by CadSoft, which offers a non-profit, DIY hobbyist license of Eagle PCB (free at time of writing) if you are able to truthfully sign and comply with their non-profit declaration.

For more detail: DIY Etching of Printed Circuit Boards (PCB)