DLP Technology

DLP technology is based on an optical semiconductor, called a Digital Micromirror Device (DMD), which uses mirrors made of aluminum to reflect light to make the picture. The DMD is often referred to as the DLP chip. The chip can be held in the palm of your hand, yet it can contain more than 2 million mirrors each, measuring less than one-fifth the width of a human hair. The mirrors are laid out in a matrix, much like a photo mosaic, with each mirror representing one pixel.

When you look closely at a photo mosaic, each piece of it holds a tiny, square photograph. As you step away from the mosaic, the images blend together to create one large image. The same concept applies to DMDs. If you look closely at a DMD, you would see tiny square mirrors that reflect light, instead of the tiny photographs. From far away (or when the light is projected on the screen), you would see a picture.

The number of mirrors corresponds to the resolution of the screen. DLP 1080p technology delivers more than 2 million pixels for true 1920x1080p resolution, the highest available.

In addition to the mirrors, the DMD unit includes:

- A CMOS DDR SRAM chip, which is a memory cell that will electrostatically cause the mirror to tilt to the on or off position, depending on its logic value (0 or 1)

- A heat sink

- An optical window, which allows light to pass through while protecting the mirrors from dust and debris

MEMS

A DMD chip is a micro electro-mechanical system (MEMS). MEMS devices combine microscopic machines with the same silicon used in a computer. See How Semiconductors Work for more information.

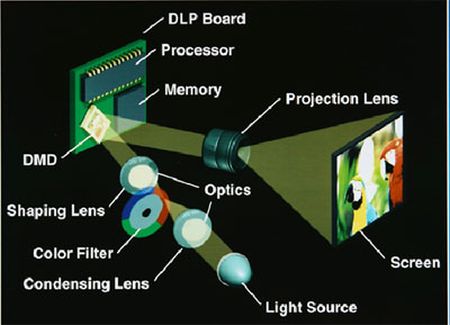

DLP Projection

Before any of the mirrors switch to their on or off positions, the chip will rapidly decode a bit-streamed image code that enters through the semiconductor. It then converts the data from interlaced to progressive, allowing the picture to fade in. Next, the chip sizes the picture to fit the screen and makes any necessary adjustments to the picture, including brightness, sharpness and color quality. Finally, it relays all the information to the mirrors, completing the whole process in just 16 microseconds.

The mirrors are mounted on tiny hinges that enable them to tilt either toward the light source (ON) or away from it (OFF) up to +/- 12°, and as often as 5,000 times per second. When a mirror is switched on more than off, it creates a light gray pixel. Conversely, if a mirror is off more than on, the pixel will be a dark gray.

The light they reflect is directed through a lens and onto the screen, creating an image. The mirrors can reflect pixels in up to 1,024 shades of gray to convert the video or graphic signal entering the DLP into a highly detailed grayscale image. DLPs also produce the deepest black levels of any projection technology using mirrors always in the off position.

To add color to that image, the white light from the lamp passes through a transparent, spinning color wheel, and onto the DLP chip. The color wheel, synchronized with the chip, filters the light into red, green and blue. The on and off states of each mirror are coordinated with these three basic building blocks of color. A single chip DLP projection system can create 16.7 million colors.

For more detail: How DLP Sets Work