Making Electronic Ink

Two companies are simultaneously developing similar electronic inks — E Ink of Cambridge, MA, and Xerox in Palo Alto, CA. At first glance, a bottle of electronic ink looks just like regular ink, but a closer examination shows something much different. Although the two companies’ products vary slightly, here are the three components of both electronic inks that give them the ability to rearrange upon command:

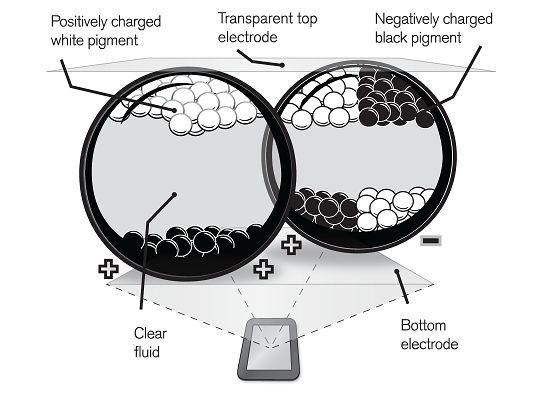

- Millions of tiny microcapsules or cavities

- An ink or oily substance filling the microcapsules or cavities

- Pigmented chips or balls with a negative charge floating inside the microcapsule

Electronic ink can be applied to the same materials that regular ink can be printed on. In the case of a digital book, the pages would be made out of some kind of ultra-thin plastic. The ink would cover the entire page, separated by cells that resemble the cells on graph paper. Think of these cells as pixels on your computer screen, with each cell wired to microelectronics embedded in this plastic sheet. These microelectronics would then be used to apply a positive or negative charge to the microcapsules to create the desired text or images.

Xerox and E Ink are using different techniques to develop their electronic inks. To help people understand how E Ink’s technology works, the company compares the millions of microcapsules inside the ink to clear beach balls. Each of these beach balls is filled with hundreds of tiny, white ping-pong balls. And instead of air, the beach ball is filled with a blue dye. If you looked at the top of this beach ball, you would see the ping-pong balls floating in the liquid, and the beach ball would appear white. But if you looked at the bottom of the ball, it would appear blue.

Now, if you were to take thousands of these beach balls and lay them out on a field, and make the ping-pong balls move between the top and bottom of the beach balls, you could make the field change color. That’s the principle behind E Ink’s product.

In reality, these microcapsules are only 100 microns wide, and roughly 100,000 microcapsules can fit into a square inch of paper. In each of those microcapsules there are hundreds of smaller pigmented chips. In prototypes, E Ink is currently working with white chips and blue ink, but it is working to develop other color inks that could lead to multicolor displays.

When an electrical charge is applied to the microcapsules, the chips will either rise to the top or be pulled to the bottom. When pushed to the top, the chips make the capsules look white; when they are pulled to the bottom, the viewer only sees the dark ink. Patterns of white and dark can then be created to form words and sentences.

Xerox is working on its own version of electronic ink, called electronic paper, which it first developed in the 1970s. However, instead of using paint chips floating in a dark liquid, it has produced microscopic balls that are black on one side and white on the other. Similar to E Ink’s technology, these microscopic balls respond to an electrical charge, which rotates the ball from black to white to produce patterns on a page. To produce pages for digital books, Xerox is developing rubber sheets in which these microscopic balls will be suspended in an oily liquid.

One of the obstacles in developing a digital book out of electronic ink has been wiring the pages to create an electrical charge while still maintaining a paper-thin page. In this aspect, E Ink has taken the lead in developing digital books by signing an agreement with Lucent Technologies that would give E Ink the rights to use plastic transistors developed by Lucent. These tiny transistors can be printed onto a page to provide the adequate charge needed to switch the E Ink chips from one color to another.

For more detail: How Electronic Ink Works