INTRODUCTION

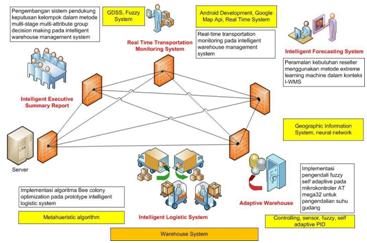

Efficient warehouse management is crucial for businesses to minimize errors and maximize productivity. Intelligent warehouse management systems aim to achieve this through integrating computer systems, equipment, and users as a unified system. This improves information quality, reduces unproductive time through fewer errors, and increases customer satisfaction through on-time deliveries of high quality goods. Higher sales then fuel business growth.

A key component of intelligent warehouse management systems is the adaptive warehouse system (AWS), which functions as the temporary storage area. It is responsible for maintaining goods quality while they await distribution scheduling. This research aims to develop an AWS prototype that can identify goods through RFID tags, control temperature and humidity using a microcontroller-based fuzzy logic controller, and meet storage quality requirements through a stable control system without overshooting.

Fuzzy logic control is well-suited for this application as warehouses involve nonlinear, environmentally influenced systems that are difficult to model mathematically. Previous research has simulated fuzzy logic control of air conditioning and greenhouses, while others have implemented fuzzy logic control hardware for computerized room cooling. This project will design and implement a fuzzy logic controller hardware design for an AWS prototype to control temperature and humidity based on RFID tag readings from goods using an ATmega32 microcontroller.

METHODOLOGY

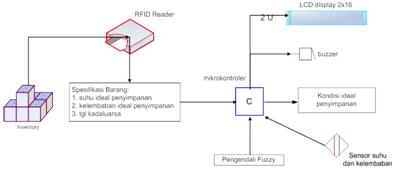

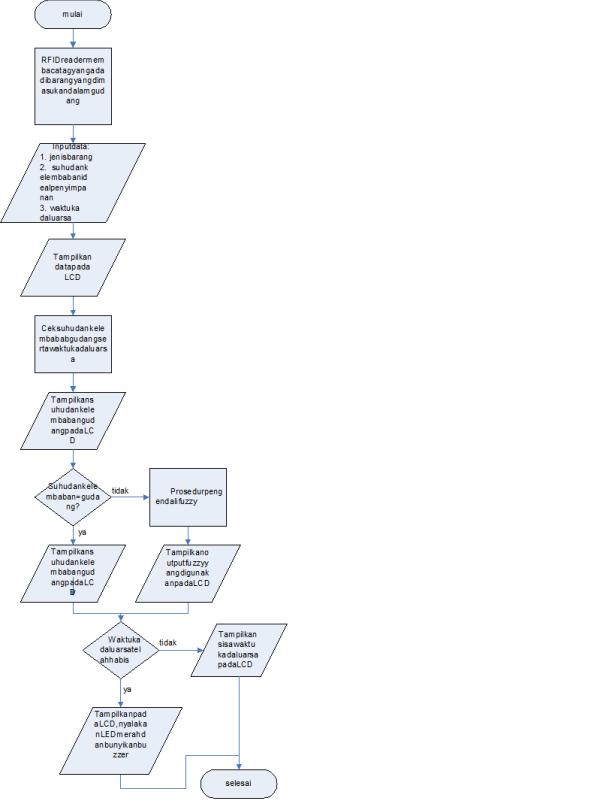

The AWS prototype will use RFID tags on goods and an RFID reader on the storage surface to detect item placement and obtain temperature/humidity requirements and expiration dates from tags. A fuzzy system will determine control parameter values based on errors between actual and required temperature/humidity. The system is designed to respond to error changes so control parameters also adjust accordingly until all goods are removed from storage.

The system process and conditions will display on an LCD. A buzzer will sound as an alarm for expiring items or incompatible temperature/humidity requirements between stored items. Hardware components include the RFID reader/tags, DHT11 temperature/humidity sensor, thermoelectric cooler actuator controlled via relays, LCD display, LED indicators, and buzzer.

The RFID reader interfaces with the microcontroller through a serial TXD/RXD connection. The DHT11 sensor communicates temperature/humidity data digitally through a single data line. Relays controlled by the microcontroller activate the 12V thermoelectric coolers as needed. The LCD requires 6 I/O pins for data/control, while individual LEDs and buzzer each use one pin with resistors.

RESULTS AND DISCUSSION

Testing confirms the RFID reader functions as expected through its serial interface. The DHT11 sensor also works digitally through a single data line. Relays properly control the 12V thermoelectric coolers in response to microcontroller commands. The LCD, LEDs, and buzzer also interface correctly with their allotted I/O pins to display conditions and provide alarms.

A Mamdani fuzzy system determines control parameters from temperature/humidity errors, error changes, and error rate of changes. Three categories are used – Negative Big, Negative Small, Zero, Positive Small, Positive Big. The microcontroller program differentiates device communication from the fuzzy logic control system flow.

Implementation requires calibration of hardware components and synchronization of data paths compared to simulation-only designs. However, results demonstrate the feasibility of directly applying this hardware-based fuzzy logic controller to control temperature and humidity in an adaptive warehouse system prototype for maintaining goods quality.

CONCLUSION

In conclusion, this research successfully designed and implemented a fuzzy logic controller hardware system on an ATmega32 microcontroller to control temperature and humidity in an adaptive warehouse system prototype. The RFID, sensor, actuator, display and alarm subsystems were all integrated and tested to function properly through their hardware interfaces and communication protocols.

While real-world implementation introduces additional calibration and synchronization challenges compared to simulation, the results validate the core approach of applying a microcontroller-based fuzzy logic controller design directly to hardware for controlling environmental conditions in a warehouse storage environment. This fuzzy logic control hardware design provides a novel solution applicable to improving goods quality maintenance in adaptive warehouse systems.

Follow this link for complete project: Design of Fuzzy Controller Hardware Based on ATmega32 Microcontroller as a Temperature and Humidity Controller