Summary of AT89C2051 DIGITAL SCALES CIRCUIT ATMEL

This article describes a digital kitchen scale project with a 2.5kg maximum capacity and 10g accuracy. It uses a strain gauge bridge sensor with an AD620 amplifier, an 8-bit TLC549 A/D converter, and an AT89C2051 microcontroller to display weight on a 4-digit LCD. Features include zero reset, overload LED and buzzer alerts, low battery indication with rechargeable Ni-Cd battery supported by a built-in charger, and automatic shutdown after 2 minutes of inactivity without weight. Detailed circuit diagrams, PCB layouts, and program functions are provided along with a simple charger design.

Parts used in the Digital Kitchen Scale Project:

- C1 100nF capacitor

- C2, C3 22pF capacitors

- C4–C8, C10, C12, C13, C15–C19 100nF capacitors (13x)

- C9 22µF/16V capacitor

- C11, C14 10µF/25V capacitors (2x)

- R1 1.8kΩ resistor

- R2–R4, R6, R7, R9, R15, R18, R22 1kΩ resistors (9x)

- R16 1kΩ SMD 1206 resistor

- R5 560Ω resistor

- R8 5.6kΩ SMD 1206 resistor

- R10–R12 4.7kΩ mini resistors (3x)

- R13, R14, R17 10kΩ resistors (3x)

- R19 1.5kΩ resistor

- R20 1.2kΩ resistor

- R21 680Ω resistor

- R23 390Ω resistor

- P1, P2 PM19K001 trimmers (2x)

- P3 PM19E500 trimmer

- P4 PT-6VK005 trimmer

- DZ1 BZX83V056 Zener diode

- DZ2 BZX83V033 Zener diode

- T1 BC560 transistor

- T2 BD140 transistor

- T3 BC546 transistor

- T4 BC556 transistor

- T5 BC327 transistor

- IO1 AT89C2051 microcontroller

- IO2 AD620 instrumentation amplifier

- IO3 TLC549 8-bit serial A/D converter

- IO4 4013 flip-flop IC

- IO5 78L05 voltage regulator

- IO6–IO9 4094 shift registers (4x)

- OZ1, OZ2 LM358 operational amplifiers (2x)

- OZ3 TL071 operational amplifier

- Q1 24MHz crystal oscillator

- DIS1 LCD3906 four-digit LCD display

- DSIR red 3mm LED (overload indicator)

- POD red 3mm LED (low battery indicator)

- Strain gauge DF2S-3 / 5kg sensor

- ZERO and ON/OFF P-0SRB push buttons (2x)

- SIR KPE242 piezo buzzer

- BAT ARK500 / 2 rechargeable Ni-Cd battery

- CIDLO ARK500 / 2 connectors (2x)

- CON1, CON2 MLW14G connectors (2x)

- PFL14 connectors (2x)

- Flat cable AWG28-14, 15 cm

- B-8F600AA battery

- Power connector K3716A

- Display frame AR1950

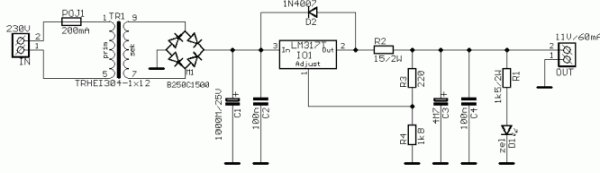

- Charger components: LM317T voltage regulator, M1 B250C1500 bridge rectifier, TR1 transformer TRHEI304-1x12, LEDs D1 green and D2 1N4007 diode, assorted resistors and capacitors for charging circuit

- Tube fuse 200mA

- Adapter box U-KZ3 and power connector SCP-2009B

This is a kitchen scale with a maximum weight of 2.5kg and an accuracy of 10g. Exceeding the range is indicated by an acoustic signal and an LED. Weight is displayed on a four-digit LCD display. The weight also includes a weight-zero reset button. The power is solved by a battery whose discharge is below the set limit indicated by the LED.Then the battery needs to be recharged, otherwise the voltage drops below the operating level and the wrong weight information appears in the display. In order to avoid having to switch off the balance for unnecessary battery discharge, after 2 minutes of inactivity (only if there is no weight on the weight) it will turn itself off.

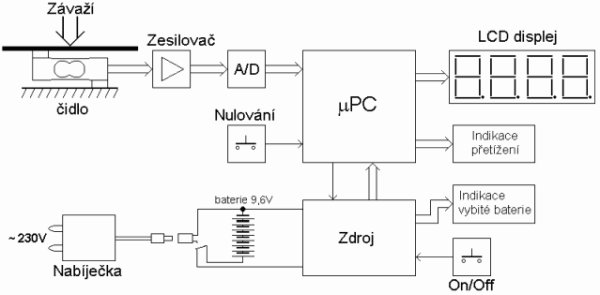

Block diagram :

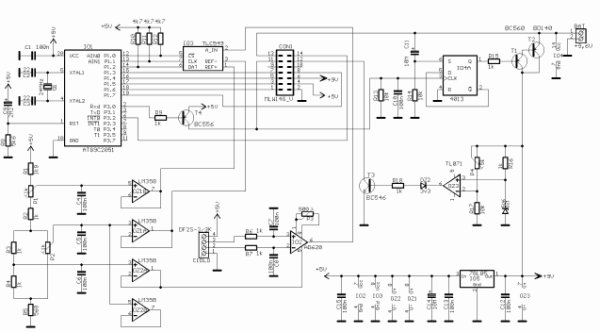

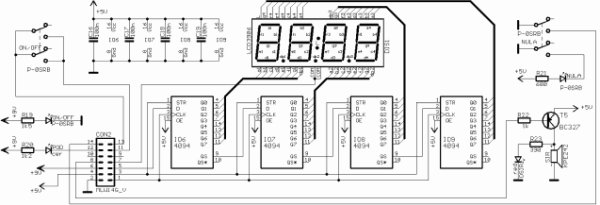

More detailed activity: Only IO4, transistor emitter T2, C11 and On / Off button are powered directly from the battery. Because the IO4 is made by CMOS technology, its take-off is minimal and hence the stand-by take-off of the whole balance when it is turned off. IO4 is connected as a T flip-flop (divider two). C11 and R14, after connecting the battery, sets output Q to log. H, the transistor T1 is closed, thereby interrupting the supply to the other part of the circuit. After pressing the button, CLK clock input is logged. H, the circuit is overturned, the transistors T1 and T2 are closed and the power balance of the rest of the balance is switched on. OZ3 is connected as a voltage comparator that monitors the battery voltage. If it drops below the set threshold by the trimmer P4, it switches on the transistor T3, which has an LED indicator in its collector and indicates a weak battery. For other circuits, we need a voltage + 5V, which is obtained from the IO5 stabilizer, C12 – C14 only serves to filter the voltage. The strain gauge sensing sensor is in the bridging circuit and at its output is a signal in the order of mV. This signal is too small for further processing, so integrated IC amplifier IO2 is connected to the circuit, its gain is 150 and is given by the Trimmer P3, which is set to 330. The amplified signal is further superimposed on the constant voltage (approximately 1 , 0 V), this is obtained from a multiple voltage divider and impedantly separated by the OZ2A operational amplifier. This amplified signal is applied to the A / D input IO3 converter. The range of the converter can be set by bringing two reference values to its REF + (about 2.7V) and REF- (about 1.1V) inputs. Both voltages are derived from the same voltage divider and impeded by OZ1. The size of the reference values can be set by the P1 and P2 trimmers to determine the lower and upper limits for the converter. According to the converter manufacturer, the difference between the reference values must always be greater than 1V. The amplified and converted signal is processed by the IO1 processor (more). The processor is in standard wiring, the C9 and R8 components ensure that when the processor reset is turned on, the Q1 crystal taps it at 24MHz.Output from the processor goes through the four 8-bit IO6-IO9 sliding registers that drive DIS1 segments on the LCD display. The common display terminal is connected directly to the processor port. Display segments need to be triggered by an AC signal with a frequency of 20 to 150 Hz (40 to 300x / s change). This means that the common outlet is set to the log. H and display the segments displayed in the log. L and vice versa the next time you broadcast. If the 2.5kg weight is exceeded (regardless of possible reset), the processor switches the transistor T5 and starts the piezo-siren SIR and the DSIR LED indicating overload. When the zero key is pressed, the processor port P3.2 is grounded, which is the input of the external interrupt and the processor remembers the current weight on the scale. If no weight is placed on the weight and is idle for 2 minutes, the transistor T4 switches on, which transmits the IO4 log to the CLK input. H, it flips and interrupts the power supply for the processor and other components except IO4. Weighing in operation is about 40mA.

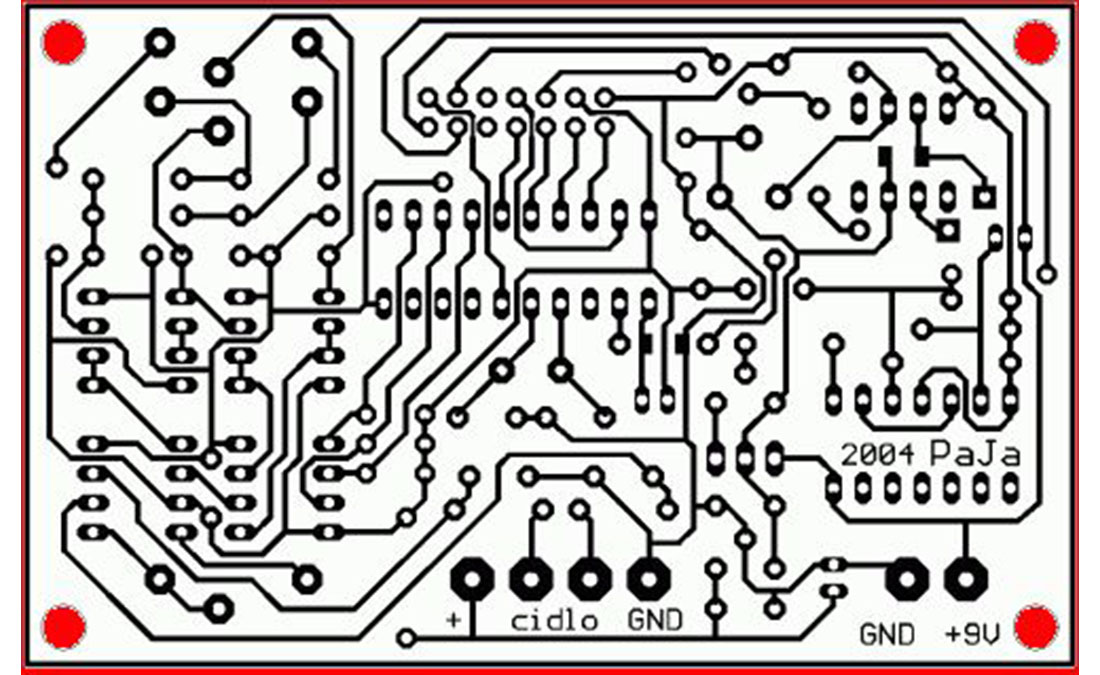

Design of printed circuit board (90 x 57 mm).

Design of printed circuit board (104 x 56 mm).

The program has about 300 lines and you can download it here – it’s complete with a lot of comments.

This is a simple charging connection for a Ni-Cd battery. This connection is not the most appropriate, but it is sufficient for occasional charging. I’ve chosen this simple connection to get the charger into the U-KPZ3 adapter box. The mains voltage is fed via a fuse to a transformer with a secondary voltage of 12V. This voltage is thrust across the M1 bridge, filtered through C1, C2 and applied to the LM317T regulated voltage stabilizer. With the R3 and R4 resistors the output voltage is set to 11.5V according to the formula U out = 1.25 (1 + R4 / R3). By R2, a constant charging current is set to 60 mA according to the formula I out = 1,25 / R2. This strain is filtered using C3, C4. The D1 LED serves only to indicate that the charger is on the network. The D2 protects the stabilizer against back-up by disabling the charger before disconnecting the rechargeable battery. It is advisable to place a small cooler on the IO1. The Ni-Cd battery is about to charge about 125% of the battery voltage, which in my case is 12V and current approximately 1/10 of the battery capacity, that is 60mA. I deliberately lowered the charging voltage to avoid potential battery damage.

C1 100n C2, C3 22p - 2x C4-C8, C10, C12, C13, C15 - C19 100n - 13x C9 22M / 16V C11, C14 10M / 25V - 2x R1 1k8 R2 - R4, R6, R7, R9, R15, R18, R22 1k - 9x R16 1k SMD 1206 R5 560 R8 5k6 SMD 1206 R10 - R12 4k7 mini - 3x R13, R14, R17 10k - 3x R19 1k5 R20 1k2 R21 680 R23 390 P1, P2 PM19K001 - 2x P3 PM19E500 P4 PT-6VK005 DZ1 BZX83V056 DZ2 BZX83V033 T1 BC560 T2 BD140 T3 BC546 T4 BC556 T5 BC327 IO1 AT89C2051 IO2 AD620 IO3 TLC549 IO4 4013 IO5 78L05 IO6 - IO9 4094 - 4x OZ1, OZ2 LM358 - 2x OZ3 TL071 Q1 24MHz | DIS1 LCD3906 DSIR LED 3mm red POD LED 3mm red Strain gauge DF2S-3 / 5kg ZERO, ON / OFF P-0SRB - 2x SIR KPE242 BAT ARK500 / 2 CIDLO ARK500 / 2 - 2x CON1, CON2 MLW14G - 2x PFL14 connectors - 2x flat cable AWG28-14 (15cm) B-8F600AA battery power connector K3716A display frame AR1950 Charger : C1 1000M / 25V C2, C4 100n - 2x C3 4M7 / 50V R1 1k5 / 2W R2 15 / 2W R3 220 R4 1k8 D1 LED 3mm green D2 1N4007 IO1 LM317T M1 B250C1500 TR1 TRHEI304-1x12 IN, OUT ARK500 / 2 - 2x POJ1 KS20-01 footrest tube fuse 200mA adapter box U-KZ3 power connector SCP-2009B cable to connect the charger to the balance |

Source: http://paja-trb.unas.cz/elektronika/konstrukce/vaha.html Digital Scales project Alternative link:at89c2051-digital-scales-circuit-atmel.RAR