Summary of Attiny13A Motor Controller Board

This project describes a motor controller board using an Attiny13A microcontroller to regulate a brushed DC motor via PWM through an IRFZ44N MOSFET. The controller operates with a single button, cycling the motor speed between 100% duty cycle, 50%, and off. The design includes a custom PCB with supporting components like a voltage regulator (AMS1117 5V) to convert 12V supply for the microcontroller. The article details schematic design, PCB fabrication at Seeed Studio, assembly steps, programming the Attiny13A, and final testing. The controller is intended for a future bladeless fan project but can be adapted for various loads.

Parts used in the Attiny13A Motor Controller Board:

- Attiny13A Microcontroller

- Custom PCB

- Brushed DC Motor

- IRFZ44N N-Channel MOSFET

- AMS1117 5V Voltage Regulator

- 10K Resistor

- 1µF Capacitor

- 10µF Capacitor

- Tactile Switch

- DIP Socket for Attiny13A

- SMD LED

- Battery Connector

- Barrel DC Jack (charging port)

So here’s something super interesting and useful, a motor controller board powered by an Attiny13A to control a Brushed DC Motor.

This Motor Driver uses PWM to control the gate of an N Channel IRFZ44N mosfet by the Tap of a single button.

I’ve added Two Modes in the code that basically controls the Duty Cycle, On First Tap the setup turns ON at 100% Duty cycle, then on the Second Tap, the Duty Cycle is half at 50%. The third Tap turns the whole setup OFF.

I made this Motor Controller board for a future project that is a Bladeless Fan Project that I will soon publish.

This Instructables is about the whole building process of this Motor Controller so let’s get started!

Supplies

Following were the materials used in this project-

- Attiny13A

- Custom PCB

- Brushed DC Motor

- IRFZ44N

- AMS1117 5V

- 10K Resistor

- 1uf Capacitor

- 10uf Capacitor

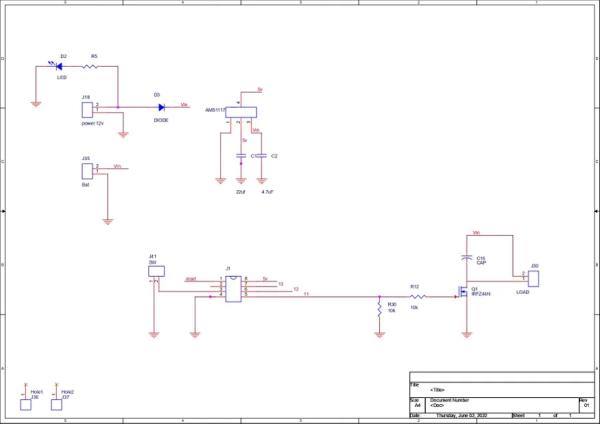

Step 1: SCHEMATIC and PCB Design

This Schematic is a simple one, there’s an N Channel Mosfet that is configured in “Mosfet as Switch setup”. This means the gate of Mosfet can be used to power the load which is, in this case, a DC Brushed Motor.

There are two Resistors connected to the Gate of Mosfet, one is connecting the gate with GND and another one is connected to the D0 Pin of Attiny13A.

I’ve used an Attiny13A to control the whole setup by using a Switch that is connected to the D4 pin and GND. By connecting D4 Pin to GND, Microcontrollers read this and provide the gate of Mosfet with a PWM signal that controls the gate of mosfet and the speed of the motor.

Now, the motor that I’m using works at 12V and above but the microcontroller needs 5V Input so to step down 12V into 5V for MCU, I’ve added an AMS1117 5V Voltage Regulator.

As for programming pins for Attiny13, I haven’t added any. Because I’m using the DIP version of attiny and I’m planning to flash attiny with my Attiny programmer that has DIP Socket for flashing the MCU.

I finalise the Schematic and prepared the PCB according to the PCB Outline that is required in my BLADELESS FAN Project.

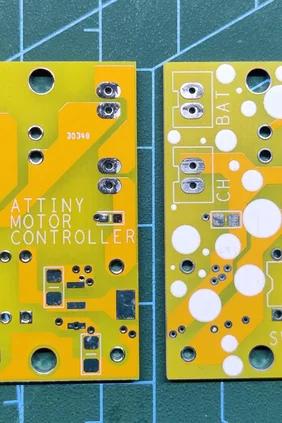

Step 2: Getting PCBs From SEEED Studio

After finalizing the PCB and generating its Gerber data, I send it to SEEED STUDIO for samples.

Ordered PCBs in Yellow Soldermask with white silkscreen.

I received PCBs in a week and their quality was super good considering the rate which was also pretty low.

Seeed Fusion PCB Service offers one-stop prototyping for PCB manufacture and PCB assembly and as a result, they produce superior quality PCBs and Fast Turnkey PCBA within 7 working days.

PCB Quality of this Motor Controller PCB WAS SUPER!

Seeed Studio Fusion PCB Assembly Service takes care of the entire fabrication process from PCB manufacturing, parts sourcing, assembly, and testing services, so you can be sure that they are getting a quality product.

After gauging market interest and verifying a working prototype, Seeed Propagate Service can help you bring the product to market with professional guidance and a strong network of connections.

Step 3: PCB ASSEMBLY

PCB Assembly of this project consists of four major steps which are

- Solder Paste Dispensing Process

- Pick & Place Process

- Hotplate Reflow

- Adding THT Components

Step 4: Solder Paste Dispensing Process

We start first by adding Solderpaste to each component pad on the bottom side of the board.

Step 5: Pick & Place Process

Then we pick and place each component in its assigned place one by one.

Step 6: Hotplate Reflow

Next, we carefully lifted the whole PCB and place it on the hotplate. I’m using my good old DIY hotplate which I made a while back.

Hotplate Heats the surface up to the solder paste melting temp and it slowly melts. after a few mins when the solder paste completely melts, we remove the PCB and let it cool down for a moment.

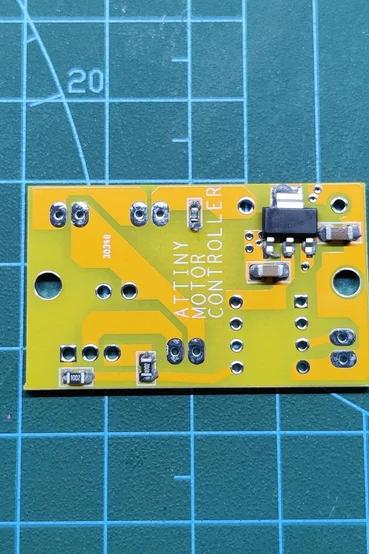

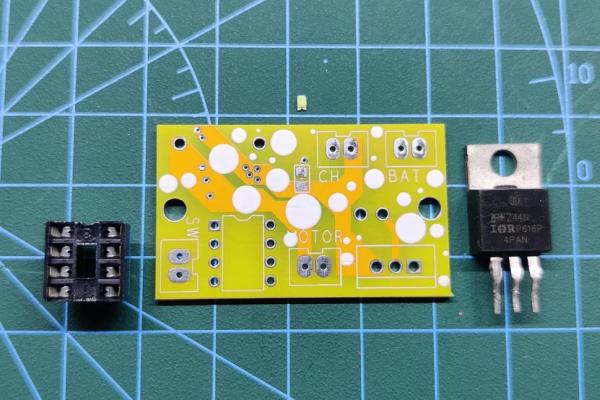

Step 7: Adding THT Components

Here’s the final setup, we place the remaining two components which are DIP Socket and Mosfet. However, we also add an SMD LED on the Top side with a soldering Iron as well, we cannot use a hotplate for placing the LED as we already place stuff on the Bottom side and this hotplate method is applicable for one side only.

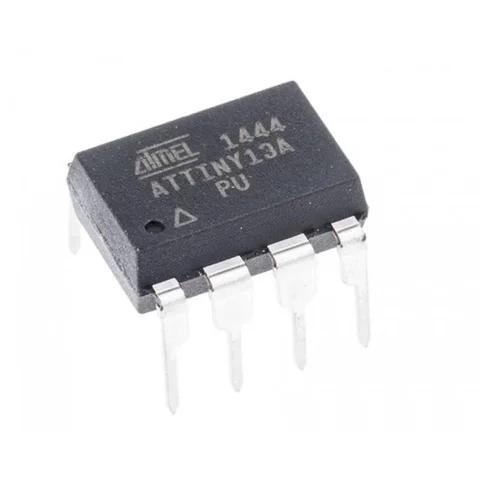

Step 8: Attiny13A and Main Code

Attiny13 is a low-power Microchip 8-bit AVR® RISC-based microcontroller that combines 1 KB ISP Flash memory, 64B SRAM, 64B EEPROM, a 32B register file, and a 4-channel 10-bit A/D converter.

I’ve used Attiny13A in this project instead of the more popular Attiny85, here’s why.

The sketch that I’m using is a pretty small sketch of size 296 bytes and Attiny13A has a total of 1024 bytes which is plenty even if we increased the functions in the preexisting sketch.

const int switchPin = 4;

const int FANPin = 0;

int FANMode = 1;

void setup()

{

pinMode(FANPin, OUTPUT);

pinMode(switchPin, INPUT_PULLUP);

digitalWrite(FANPin, LOW);

}

void loop()

{

if (digitalRead(switchPin) ==LOW)

{

FANMode = FANMode + 1;

if (FANMode == 4)

{

FANMode = 1;

}

}

if (FANMode == 1)

{

digitalWrite(FANPin, LOW);

delay(200);

}

else if (FANMode == 2)

{

digitalWrite(FANPin, HIGH);

delay(200);

}

else if (FANMode == 3)

{

analogWrite(FANPin, 50);

delay(200);

}

//delay(200); // see text

}Attiny85 is a much more advanced MCU with 8 KB ISP Flash memory, 512B EEPROM, 512B SRAM. It’s suitable for more demanding projects like running two or three servos at the same time with three I/O Pins or driving Neopixels.

It would be overkill to use an Attiny85 to run a single motor with a button so that’s the main reason for using Attiny13A.

Also, Attiny13A is inexpensive compared with an Attiny85.

As for the flashing process of Attiny13A, check out this post of mine for more details.

https://www.instructables.com/Multiple-ATtiny8513A-Programmer/

After burning the bootloader and uploading the sketch in the ATtiny13A, we place the Attiny in its DIP Socket and move onto the final assembly of the board.

Step 9: FINAL ASSEMBLY STEP 1- Adding Switch

We start by adding a Tactile switch to the circuit’s Switch Connector.

A CN2515 connector can also be used instead of direct soldering the switch.

Step 10: STEP 2- Adding Motor

Next, we add DC Motor to its assigned connector pins, I’m manually soldering the wire instead of using a connector, the main and final version that I will use in my Bladeless Fan project will have connectors and wire harness and won’t have any solder joints.

Step 11: STEP 3- Adding Battery

We then add the battery’s Positive and Negative terminals to the battery connector in the right polarity. Now the circuit is alive. However, there’s the last thing left to add which is the charging port.

Step 12: STEP 4- Adding Charging Port

At last, we add a barrel DC Jack to the charging port so we can later add a 12V Adaptor for charging the battery.

Step 13: RESULT

Here’s the result.

As soon as we press the switch, the motor turns ON at max speed.

The second Tap reduces its speed by 50%, the third Tap turns everything OFF.

Its working is pretty simple and if we want, we can add more modes like increasing the Motor Speed by adding more Tap function that increases or decreases the speed of the motor.

Because we are using IRFZ44N Mosfet, we can drive the motor up to 55V at 49A which is insane but it would require a huge heatsink as we increase the motor power.

In my case, Motor Draws 12V at 0.500A at High Mode which is pretty low and sufficient for my application.

As for the alternate use for the circuit, we can use this circuit in anything that operates over 5V, Lights, motors, and even resistive elements.

Just make sure to add a heatsink if the load is heavy.

All the Docs related to the project are attached. If you need any help regarding this project, DM me or comment.

Special thanks to Seeed Studio for providing PCBs for this project. Do check them out if you need great PCB Service for less cost.

Source: Attiny13A Motor Controller Board