Desoldering braid makes an invaluable service at development or rework.

Everyone who´s ever tried to suck off a solder from a solder pad by means of a solder absorbing braid (wick) will probably confirm, that this tool belongs to a “must have” equipment of every professional or amateur workplace. What´s the charm of a desoldering braid? Above all in the fact, that it´s able to absorb almost all the solder from a given place, thus the most of components can be loosened very easily. Hand (pneumatic) pump surely has its place, mainly when working with bigger components, but at comparison with a desoldering braid it´s similar like if we compared a broom with a vacuum cleaner.

A quality desoldering braid is usually able to absorb a solder so thoroughly, that only a microscopic layer of a solder will remain on a PCB – as if a board was new, unused. It is very advantageous even at a hand rework of SMT components, because it´s desirable the component to lay directly on a board – not askew in a thick solder layer causing a mechanical tension and able to cause even a malfunction of a component (often at SMT capacitors).

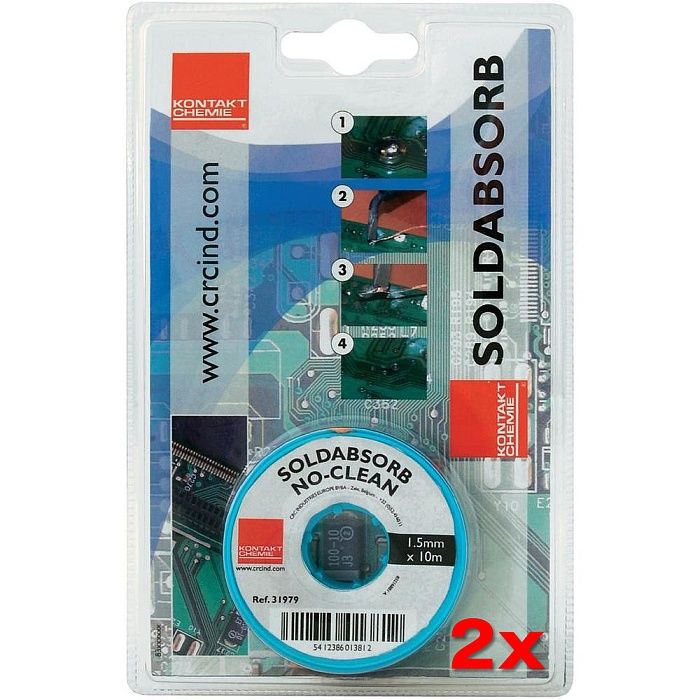

For more detail: Desolder professionally with NO-CLEAN flux wicks