Flexible circuit boards offer numerous advantages. However, the mechanical fixation of these circuit boards is highly complex. HARTING has developed a new solution based on 3D-MID technology that is capable of replacing flexible circuit boards. Thanks to component carriers, cost savings of up to two-thirds can be achieved.

At the MID process, on the injection molded part a customized layout is applied. At the electronic assembly, the components are mounted on the desired surface.

Flexible printed circuit boards made of thin polyimide films have established themselves in many product areas thanks to their application flexibility. Populating and assembling them, however, is decidedly more complex. This is where a newly developed component carrier from HARTING enters the picture.

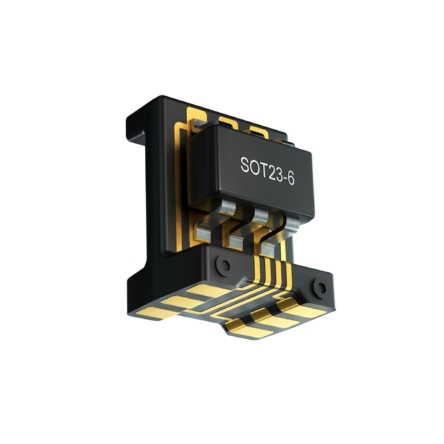

A standardized component carrier for electronic components

By harnessing this all new HARTING development, electronic components can be fitted directly onto the component carrier, thereby replacing flexible circuit boards. The component carrier serves as a connecting element between the printed circuit board (PCB) and electronic components such as LEDs, ICs, photodiodes and sensors.

Electronic components are mounted directly on the new component carrier in automated processes. The frequently complex processes involved in processing flexible circuit boards is dispensed with, thereby reducing costs by up to two-thirds.

Read more: HARTING EUROPE, COMPONENT CARRIER NOW REPLACING FLEXIBLE PCBS