OLED Components

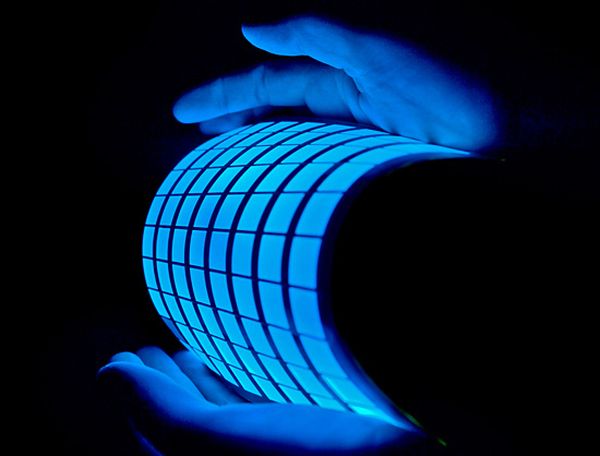

Like an LED, an OLED is a solid-state semiconductor device that is 100 to 500 nanometers thick or about 200 times smaller than a human hair. OLEDs can have either two layers or three layers of organic material; in the latter design, the third layer helps transport electrons from the cathode to the emissive layer. In this article, we’ll be focusing on the two-layer design.

An OLED consists of the following parts:

Substrate (clear plastic, glass, foil) – The substrate supports the OLED.

Anode (transparent) – The anode removes electrons (adds electron “holes”) when a current flows through the device.

Organic layers – These layers are made of organic molecules or polymers.

Conducting layer – This layer is made of organic plastic molecules that transport “holes” from the anode. One conducting polymer used in OLEDs is polyaniline.

Emissive layer – This layer is made of organic plastic molecules (different ones from the conducting layer) that transport electrons from the cathode; this is where light is made. One polymer used in the emissive layer is polyfluorene.

Cathode (may or may not be transparent depending on the type of OLED) – The cathode injects electrons when a current flows through the device.

The biggest part of manufacturing OLEDs is applying the organic layers to the substrate. This can be done in three ways:

- Vacuum deposition or vacuum thermal evaporation (VTE) – In a vacuum chamber, the organic molecules are gently heated (evaporated) and allowed to condense as thin films onto cooled substrates. This process is expensive and inefficient.

- Organic vapor phase deposition (OVPD) – In a low-pressure, hot-walled reactor chamber, a carrier gas transports evaporated organic molecules onto cooled substrates, where they condense into thin films. Using a carrier gas increases the efficiency and reduces the cost of making OLEDs.

- Inkjet printing – With inkjet technology, OLEDs are sprayed onto substrates just like inks are sprayed onto paper during printing. Inkjet technology greatly reduces the cost of OLED manufacturing and allows OLEDs to be printed onto very large films for large displays like 80-inch TV screens or electronic billboards.

How do OLEDs Emit Light?

OLEDs emit light in a similar manner to LEDs, through a process called electrophosphorescence.

The process is as follows:

- The battery or power supply of the device containing the OLED applies a voltage across the OLED.

- An electrical current flows from the cathode to the anode through the organic layers (an electrical current is a flow of electrons). The cathode gives electrons to the emissive layer of organic molecules. The anode removes electrons from the conductive layer of organic molecules. (This is the equivalent to giving electron holes to the conductive layer.)

- At the boundary between the emissive and the conductive layers, electrons find electron holes. When an electron finds an electron hole, the electron fills the hole (it falls into an energy level of the atom that’s missing an electron). When this happens, the electron gives up energy in the form of a photon of light (see How Light Works).

- The OLED emits light.

- The color of the light depends on the type of organic molecule in the emissive layer. Manufacturers place several types of organic films on the same OLED to make color displays.

- The intensity or brightness of the light depends on the amount of electrical current applied: the more current, the brighter the light.

For more detail: How OLEDs Work