Summary of How Pendulum Clocks Work

The article explains the key components and working principles of pendulum clocks, which have remained largely unchanged since 1656. A pendulum clock typically consists of a clock face with hands, a weight-driven energy mechanism, and a pendulum. The weight stores potential energy that drives the clock as it falls, while the pendulum regulates the timing due to its period being solely dependent on its length and gravity, ensuring accuracy. Attempts to control clock speed by friction proved unreliable, leading to the adoption of the pendulum for precise timekeeping, as first suggested by Christiaan Huygens.

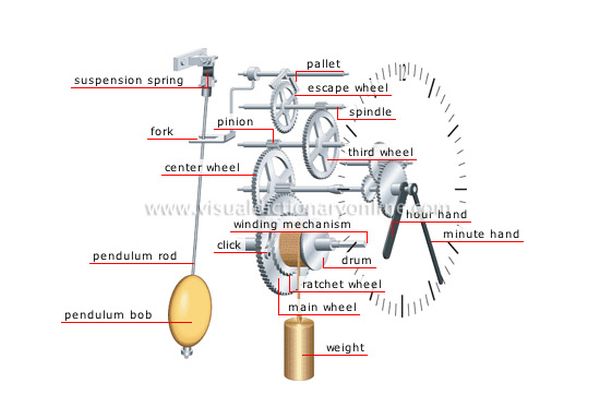

Parts used in the Pendulum Clock:

- Clock face with hour and minute hands

- Moon phase dial (optional)

- Weights (for weight-driven clocks)

- Pendulum

- Cord for lifting weights

- Drum to which cord and hands are attached

Pendulum Parts

Pendulum clocks have been used to keep time since 1656, and they have not changed dramatically since then. Pendulum clocks were the first clocks made to have any sort of accuracy. When you look at a pendulum clock from the outside, you notice several different parts that are important to the mechanism of all pendulum clocks:

- There is the face of the clock, with its hour and minute hand (and sometimes even a “moon phase” dial).

- There are one or more weights (or, if the clock is more modern, a keyhole used to wind a spring inside the clock — we will stick with weight-driven clocks in this article).

- And, of course, there is the pendulum itself.

In most wall clocks that use a pendulum, the pendulum swings once per second. In small cuckoo clocks the pendulum might swing twice a second. In large grandfather clocks, the pendulum swings once every two seconds. So, how do these parts work together to keep the clock ticking and the time accurate? Let’s take a look at the weight, first.

A Weighty Subject

The idea behind the weight is to act as an energy storage device so that the clock can run for relatively long periods of time unattended. When you “wind” a weight-driven clock, you pull on a cord that lifts the weight. That gives the weight “potential energy” in the Earth’s gravitational field. As we will see in a moment, the clock uses that potential energy as the weight falls to drive the clock’s mechanism.

So let’s say that we wanted to use a falling weight to create the simplest possible clock — a clock that has just a second hand on it. We want the second hand on this simple clock to work like a normal second hand on any clock, making one complete revolution every 60 seconds. We might try to do that, as shown in the figure on the right, simply by attaching the weight’s cord to a drum and then attaching a second hand to the drum as well. This, of course, would not work. In this simple mechanism, releasing the weight would cause it to fall as fast as it could, spinning the drum at about 1,000 rpm until the weight clattered on the floor.

Still, it’s headed in the right direction. Let’s say we put some kind of friction device on the drum — some sort of brake pad or something that would slow the drum down. This might work. We would certainly be able to devise some scheme based on friction to get the second hand to make approximately one revolution per minute. But it would only be approximate. As the temperature and the humidity in the air changed, the friction in the device would change. Thus our second hand would not keep very good time.

So, back in the 1600s, people who wanted to create accurate clocks were trying to solve the problem of how to cause the second hand to make exactly one revolution per minute. The Dutch astronomer Christiaan Huygens is credited with first suggesting the use of a pendulum. Pendulums are useful because they have an extremely interesting property: The period (the amount of time it takes for a pendulum to go back and forth once) of a pendulum’s swing is related only to the length of the pendulum and the force of gravity. Since gravity is constant at any given spot on the planet, the only thing that affects the period of a pendulum is the length of the pendulum. The amount of weight does not matter. Nor does the length of the arc that the pendulum swings through. Only the length of the pendulum matters. If you’re not convinced, try the experiment on the following page!

For more detail: How Pendulum Clocks Work