Summary of OPERATED WASHING MACHINE CONTROL CIRCUIT WITH ATMEGA32

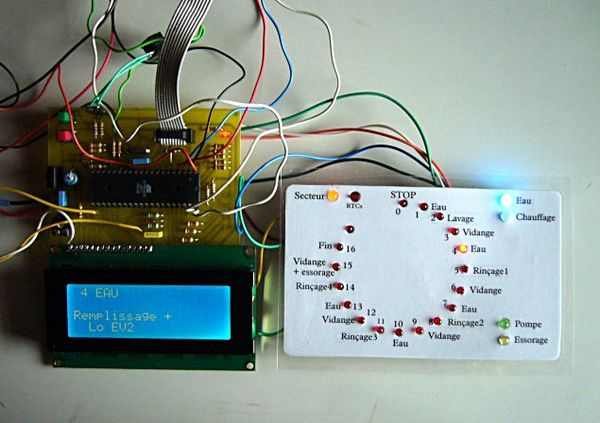

This project features an ATmega32 microcontroller-based washing machine control circuit that precisely manages motor speed, direction, and other functions. The microcontroller uses triacs controlled via opto-isolators (MOC3043 and MOC3023) to adjust 230V motor voltage and maintain a constant drum speed by measuring feedback from a tachogenerator. Additional components control the pump, valves, and heater. The low-voltage control circuitry is isolated from the high-voltage mains. The system can be operated remotely through an IR TV remote, enhancing user convenience.

Parts used in the Washing Machine Control Circuit:

- ATmega32 microcontroller

- MOC3043 opto-triac (zero crossing detector)

- MOC3023 opto-triac (instantaneous response, zero crossing)

- 230V triacs for motor and pump control

- 230V – 10A relay for heater control

- Transformer 230V to 2x6V

- Tachogenerator for motor speed feedback

- Resistive temperature sensor

- LCD display (20 characters, blue backlight)

- LED indicators (multiple colors)

- IR remote control receiver

- Buttons for manual input

- Relays for motor rotation direction switching

ATmega32 microcontroller based on the project is already quite interesting and a professional I see this type of advanced projects ATMEL series Some sections of the circuit MOC3043 opto diac, MOC3023 isolated with LCD… Electronics Projects, Operated Washing Machine Control Circuit with ATmega32 “avr project, microcontroller projects, “

ATmega32 microcontroller based on the project is already quite interesting and a professional I see this type of advanced projects ATMEL series

Some sections of the circuit MOC3043 opto diac, MOC3023 isolated with LCD and LED indicator control (presumably rc5) control and has a lot more features

WASHING MACHINE CIRCUIT

The rotational speed of the motor is controlled by the microcontroller. Its supply voltage 230V is cut by a triac controlled by the ATmega. Indeed, directly powered by 230V motor rotates the spin speed. It should therefore be slow for washing. But the speed control is rendered necessary because the torque varies alot during each revolution of the drum of the distribution and movement of the laundry in the drum. Hence the presence of the tachogenerator of the motor shaft. the ATmega continuously measures the actual speed of the drum (by a function programmed frequency) and compares it with a setpoint. The result is used to adjust the angle of the triac to maintain constant speed (speed control). This is one of the finer points of the program.

The direction of rotation of the motor is selected by switching the connection of the stator relative to the rotor by two relays. The pump and valves are controlled by triacs. The heater is controlled by a relay 230V – 10A.

The microcontroller circuits and low voltage (5V) are isolated from the 230V mains:

feeding a transformer 230V – 2X6V

triacs by opto-triacs detecting zero crossing MOC3043.

cutting the triac motor voltage by an opto-triac NO detecting zero crossing MOC3023 (instantaneous response)

Everything is managed remotely by a remote control for TV! (it avoids touching anything during operation of the machine)

SOME FEATURES OF THE CONTROL BOARD;

1) Check-out: Engine speed control on-off control drain pump water inlet temperature control to 20 characters (blue) LCD. Some LEDs in all colors

2) Input: rev counter with resistive temperature sensor reference signal phase 50Hz sector. Buttons, buttons, IR remote control receiver

Source: https://320volt.com/en/atmega32-ile-kumandali-camasir-makinasi-kontrol-karti/ alternative link: operated-washing-machine-control-circuit-with-atmega32.rar alternative link2