Summary of Servo Motor Control by Using AVR ATmega32 Microcontroller

This article explains the use of hobby servo motors, specifically the Futaba S3003, controlled via AVR microcontrollers using PWM signals. Servos are ideal for precise angle positioning rather than continuous rotation, commonly used in RC cars, robotics, and aircraft rudders. The control signal is a 50Hz PWM with pulse width determining the servo angle. The article details configuring the AVR ATmega32 timer1 in Mode 14 (Fast PWM) with a 16MHz CPU clock and prescaler 64 to generate the required pulses. Sample code is provided to sweep the servo through various angles using OCR1A values. Hardware setup uses a standard AVR development board with 5V supply.

Parts used in the Servo Motor Control by Using AVR ATmega32 Microcontroller:

- Futaba S3003 Hobby Servo Motor

- ATmega32 or ATmega16 Microcontroller

- 16 MHz Crystal Oscillator

- 5V Regulated Power Supply

- Basic AVR Development Board (e.g. Low Cost AVR Development Board or xBoard v2)

- Connecting wires (Red for +5V, Black for GND, White for control signal)

- ISP Programmer (e.g. USB AVR Programmer v2.0) for uploading hex files

Servo motors are a type of electromechanical actuators that do not rotate continuously like DC/AC or stepper motors, rather they used to position and hold some object. They are used where continuous rotation is not required so they are not used to drive wheels (unless a servo is modified). In contrast they are used where something is needed to move to particular position and then stopped and hold there. Most common use is to position the rudder of aircrafts and boats etc. Servos can be used effectively here because the rudder do not need to move full 360 degrees nor they require continuous rotation like a wheel. The servo can be commanded to rotate to a particular angle (say 30) and then hold the rudder there. Servos also employs a feedback mechanism, so it can sense an error in its positioning and correct it. This is called servomechanism. So if the air flow exerts pressure on rudder and deflects it the servo will apply force in opposite direction and try to correct the error. Say if you ask servo to go and lock itself to 30 degrees and then try to rotate it with your hand, the servo will try hard and its best to overcome the force and keep servo locked in its specified angle.

Servos are also used to control the steering of RC cars, robotics arms and legs.

Their are many types of servos but here we will concentrate on small hobby servos. Hobby servo has motor and its control mechanism built into one unit. They have 3 wire connector. One is for positive supply other for ground and the last one for control signal. The image below shows a common hobby servo from Futaba, its S3003.

Futaba S3003 wiring.

- RED -> Positive supply 4.8v to 6v

- BLACK -> GND

- WHITE -> Control Signal.

Controlling a Servo Motor.

Controlling a servo is easy by using a microcontroller, no external driver like h-bridge etc are required. Just a control signal is needed to be feed to the servo to position it in any specified angle. The frequency of the control signal is 50hz (i.e. the period is 20ms) and the width of positive pulse controls the angle.

Servo Motor Control Signal. |

For Futaba 3003 servos, I found out the following timings. The relation between the width of pulse and servo angle is given below. Note that these servos are only capable of rotating between 0 and 180 degrees.

- 0.388ms = 0 degree.

- 1.264ms = 90 degrees. (neutral position)

- 2.14ms = 180 degrees.

Controlling Servo Motors with AVR Microcontrollers.

You can use the AVR micro controllers PWM feature to control servo motors. In this way the PWM with automatically generate signals to lock servo and the CPU is free to do other tasks. To understand how you can setup and use PWM you need to have basic understanding of hardware timers and PWM modules in AVR. The following articles may be of great help.

- Introduction to PWM

- Generating PWM Signals by using AVR Timers.

- Introduction to AVR Timers.

- Timers in compare Mode.

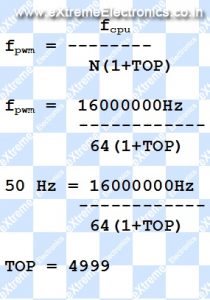

Here we will use AVR Timer1 Module which is a 16bit timer and has two PWM channels(A and B). The CPU frequency is 16MHz, this frequency is the maximum frequency that most AVRs are capable of running. And so it is used in most development board like Low Cost AVR Development Board and xBoards. We chose the prescaler as 64. So the timer will get 16MHz/64 = 250khz (4 uS period). We setup Timer Mode as Mode 14.

Timer Mode 14 features

- FAST PWM Mode

- TOP Value = ICR1

So the timer will count from 0 to ICR1(TOP Value). The formula for PWM frequency and calculation for TOP value is given below

So we set up ICR1A=4999, this gives us PWM period of 20ms (50 Hz). Compare Output Mode is set by correctly configuring bits COM1A1,COM1A0 (For PWM Channel A) and COM1B1,COM1B0(For PWM Channel B)

COM1A1 = 1 and COM1A0=0 (for PWM Channel A)

COM1B1 = 1 and COM1B0=0 (for PWM Channel B)

The above settings clears the OC1A (or OC1B) pin on Compare Match and SET ( to high) at BOTTOM. The OC1A and OC1B pins are the PWM out pin in ATmega16/ATmega32 chips. This settings gives us NON inverted PWM output.

Now the duty cycle can be set by setting OCR1A and OCR1B registers. These two register controls the PWM high period. Since the period of timer is 4uS (remember 16Mhz divided by 64?) we can calculate values required for following servo angles.

- Servo Angle 0 degrees require pulse width of 0.388ms(388uS) so value of OCR1A = 388us/4us = 97

- Servo Angle 90 degrees require pulse width of 1.264ms(1264uS) so value of OCR1A = 1264us/4us = 316

- Servo Angle 180 degrees require pulse width of 2.140ms(2140uS) so value of OCR1A = 2140us/4us = 535

If you are using Vigor VS-10 (High Torque Servo) then you need the following values.

- Set OCR1A=180 for 0 degree.

- Set OCR1A=415 for 90 degree.

- Set OCR1A=650 for 180 degree.

In this way you can calculate the value of OCR1A( or OCR1B for second servo) for any angle required. We can see that the value of OCR1x varies from 97 to 535 for servo angle of 0 to 180 degrees.(180 to 650 in case of Vigor VS-10)

Complete AVR ATmega32 Code for Servo Motor Control Demo.

The demo program given below shows how to use servo motors with AVR microcontroller. The job of the program is very simple, it starts by initializing the timer and pwm. Then it locks the servo at 0 degree, then moves it to 90 degree and wait for australian pokies some time, then similarly goes to 135 degree and finally to 180 degrees. The process is repeated as long as powered.

Some Parameter for proper working of program.

- LOW Fuse = 0xFF and HIGH Fuse = 0xC9

- Crystal Frequency = 16MHz.

- Servo Motor is branded Futaba S3003.

- MCU is ATmega32 or ATmega16.

/******************************************************************************

Program to demonstrate the use servo motors with AVR Microcontrollers.

For More Details Visit: http://www.eXtremeElectronics.co.in

Copyright (c) 2008-2010

eXtreme Electronics, India

Servo Motor: Futaba s3003

Servo Control PIN (white): To OC1A PIN

Crystal: 16MHz

LOW Fuse: 0xFF

HIGH Fuse: 0xC9

Compiler:avr-gcc toolchain

Project Manager/IDE: AVR Studio

NOTICE

--------

NO PART OF THIS WORK CAN BE COPIED, DISTRIBUTED OR PUBLISHED WITHOUT A

WRITTEN PERMISSION FROM EXTREME ELECTRONICS INDIA. THE LIBRARY, NOR ANY PART

OF IT CAN BE USED IN COMMERCIAL APPLICATIONS. IT IS INTENDED TO BE USED FOR

HOBBY, LEARNING AND EDUCATIONAL PURPOSE ONLY. IF YOU WANT TO USE THEM IN

COMMERCIAL APPLICATION PLEASE WRITE TO THE AUTHOR.

WRITTEN BY:

AVINASH GUPTA

[email protected]

*******************************************************************************/

#include <avr/io.h>

#include <util/delay.h>

//Simple Wait Function

void Wait()

{

uint8_t i;

for(i=0;i<50;i++)

{

_delay_loop_2(0);

_delay_loop_2(0);

_delay_loop_2(0);

}

}

void main()

{

//Configure TIMER1

TCCR1A|=(1<<COM1A1)|(1<<COM1B1)|(1<<WGM11); //NON Inverted PWM

TCCR1B|=(1<<WGM13)|(1<<WGM12)|(1<<CS11)|(1<<CS10); //PRESCALER=64 MODE 14(FAST PWM)

ICR1=4999; //fPWM=50Hz (Period = 20ms Standard).

DDRD|=(1<<PD4)|(1<<PD5); //PWM Pins as Out

while(1)

{

OCR1A=97; //0 degree

Wait();

OCR1A=316; //90 degree

Wait();

OCR1A=425; //135 degree

Wait();

OCR1A=535; //180 degree

Wait();

}

}

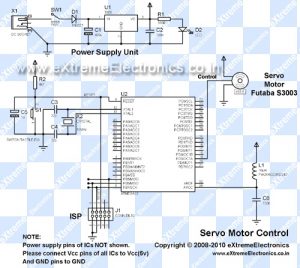

Hardware

You need a basic avr circuit with 5v regulated supply, 16 MHz crystal and proper reset circuit. All these are present in most common development boards.

AVR ATmega32 Controlling a Futaba Servo Motor. |

If you have development boards like Low Cost AVR Development Board or xBoard v2. Then you just need to add the servo motor. Connect RED wire of servo to 5v, BLACK wire to GND and the WHITE wire to OC1A PIN.

The RED Arrow Show the Position of OC1A pin on xBoard v2.0

The RED Arrow Show the Position of OC1A pin.

OC1A PIN is multiplexed with PD5 GPIO pin, that’s why the Low Cost AVR Development Board it is Marked as PD5. The RED Circle in above image is where you can find the 5v and GND supplies. So adding a servo in development board is very easy.

Downloads

- Source Code.

- Complete AVR Studio Project For ATmega16(VS-10 Servo).

- HEX File for ATmega32.

- HEX File for ATmega16 (VS-10 Servo).

- HEX File for ATmega32 (VS-10 Servo).

- Only Servo.c file

- Proteus Simulation for quick testing

NOTE: HEX File can be uploaded to the boards by using a ISP Programmer like the USB AVR Programmer v2.0

Videos

The video demo of above program.

Using VS-10 High Torque Servo

Read More: Servo Motor Control by Using AVR ATmega32 Microcontroller