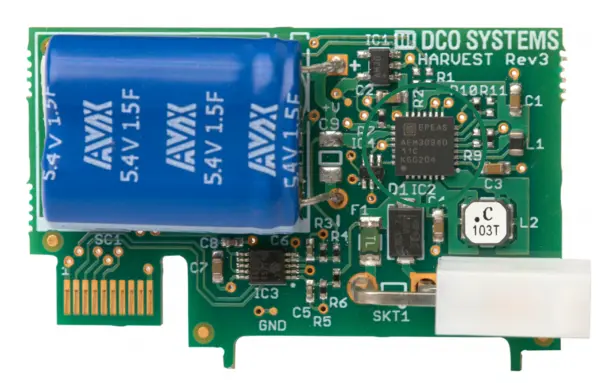

Supercapacitors, ultracapacitors, and electric double layer capacitors. No matter to which they are referred, this passive electronics component has some very desirable properties for the Internet of Things (IoT), smart wearables, and energy harvesting markets. Supercapacitors are ideal for providing efficient power pulses for transmitting data and rapidly collecting energy from intermittent sources, and to top it all off, allow for a near infinite cycle life, preventing the need to stress over battery management and replacement. However, traditional rigid, cylinder- and rectangular-shaped supercapacitors unnecessarily limit product design as they are restricted to use on a circuit board or are so large they need a dedicated storage space in which the component may reside. In IoT devices, they use about ~50% of the surface area (space) available on the printed circuit board (PCB).

A plethora of modern programmable chips, electronic components, and sensors are available in sizes comparable to as small as grain of sand to only as large as a dime. In relation, energy storage components, such as batteries and supercapacitors, are thousands of times larger and make up the bulk of design intent. This creates a “tail-wagging-the-dog” constraint. The active electronics should dictate the size of the PCB, not the passive energy storage devices and components. All too frequently the energy storage device prevents flexibility in the size and shape of the final product, inhibiting the opportunity for product miniaturization and/or product improvement.

Capacitech’s Cable-Based Capacitor (CBC) innovation, which may be found on their website, dramatically improves the form factor of supercapacitors offering a thin, flexible, and wire-like shape, allowing the CBC’s to be used in cabling infrastructure and mechanical arrangements where the traditional cylinder, rectangular, or even flat supercapacitors are unable to fit. It can be used to streamline product design and offer features that are not possible with a traditional supercapacitors. It seems simple, but implementing CBC technology in the wiring harness of a product or around a PCB rather than on the face of a PCB will free quite a bit of “real estate,” so to speak.

Read more: FLEXIBLE ELECTRONICS LET FORM FOLLOW FUNCTION