How to Route Differential Pairs in Autodesk EAGLE

If you’re designing a high speed PCB, then chances are you’re working with the latest and most powerful technologies, like HDMI, USB3.0, Ethernet, or DDR. But with great power comes great responsibility! As a result, you’ll likely be dealing with issues like electromagnetic interference (EMI) and noise.

So what do you do about these problems? When you’ve got a bunch of noisy signals on your board and you need a way to protect the transmission of your data then you need to be using differential pairs. In this blog we’ll be looking at all of the great benefits for using differential pairs in your high speed design project, and how to route them in Autodesk EAGLE.

It’s a Dual Benefit

Differential pairs are the physical manifestation of putting differential signaling into action on your high speed PCB layout. Put simply, this is the process of using not just one, but two traces to transmit a signal on your board. These two traces both carry the same signal. The first trace, considered positive, carries your original signal. And the second trace, considered negative, carries the inverse of the original signal.

Here’s differential signaling (bottom) and single-end signaling (top) side by side. (Image source)

Why would you ever want to carry the same signal along two traces? There are a ton of reasons, such as:

- Separating power systems. Differential signals don’t typically send a return signal to ground, and because of this, you don’t need to worry about crossing over power boundaries. This can make it a lot easier to keep your power systems separate.

- Reducing electromagnetic interference. Your tightly coupled differential signals are great at resisting any EMI emissions from other noisy traces on your board layout. They also cancel out their own EMI emissions with their shared polarity and distance.

- Precisely timing. It’s also a lot easier to determine what kind of logic state a differential pair is at in any given moment. If the negative trace has a higher voltage than the positive one, then it has a higher logic state, and if it’s the other way around, then the pair has a low logic state.

While differential pairs do have a ton of advantages when it comes to resisting electromagnetic interference and noise, they also have some particular design rules that you need to pay attention to. These include:

Rule 1 – Keep differential signal traces at equal lengths. Your differential pairs are only beneficial when their lengths are kept the same, which keeps their polarity in balance.

Rule 2 – Route differential traces close together. The closer you route your differential pairs together, the less EMI they will emit on your PCB layout.

Rule 3 – Define your impedance. You need to always keep your differential pair impedance constant over its entire length. This will depend on the width of your traces, your copper thickness, and your layer stackup materials.

We’re going to avoid giving any hard and fast numbers about the design rules that we outlined above. Why? Because the constraints of your differential pairs are largely dependent on the unique composition of your design. We’ll be teaching you how to route differential pairs, but defining the details in your design rules is up to you. Ready to get started? Here’s how we’re going to break down the routing of differential pairs in Autodesk EAGLE:

- Step 1 – Define Your Net Class. You first need to create a new net class that you can use to apply width rules to your differential traces.

- Step 2 – Define Your Net Names. You then need to change the name of your nets, so Autodesk EAGLE recognizes them as differentials.

- Step 3 – Apply Your Net Class. You’ll then apply the net class you created in Step 1 to each of your nets.

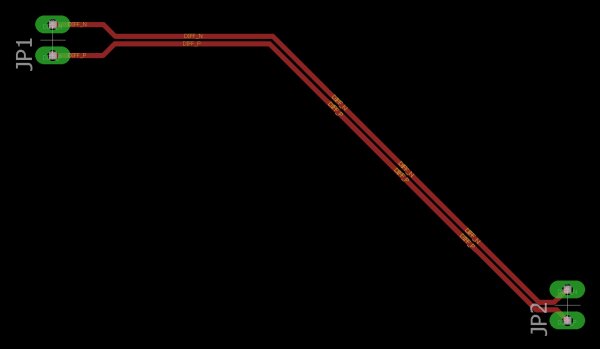

- Step 4 – Route Your Differential Pairs. Lastly, you’ll use the Routing tool in Autodesk EAGLE to route your differential pairs to their intended destination.

Step 1 – Define Your Net Class

Before you start routing any differential pairs, it’s a good practice to create a net class that can control the width of your traces. Net classes come in really handy when you want to apply the same set of rules for widths, drill sizes, and clearances for a group of nets on your board. Here’s how to do this:

- Open your PCB layout (.brd) file from the Autodesk EAGLE Control Panel.

- Select Edit at the top of your interface, then choose Net classes to open the Net classes dialog.

- Next, give your net class a name, then specify a width value. In our example, we’re giving our net class a name of “diff pairs” and a width of 16 mils.

Read more: How to Route Differential Pairs