This document describes the construction of a PCB drill machine driven by a master-controller board and three stepper motor driver boards. These four single sided PC boards each contain an Atmega16/32 microcontroller. Communication between… Electronics Projects, ATMEGA32 PCB drill machine “avr project, microcontroller projects, “

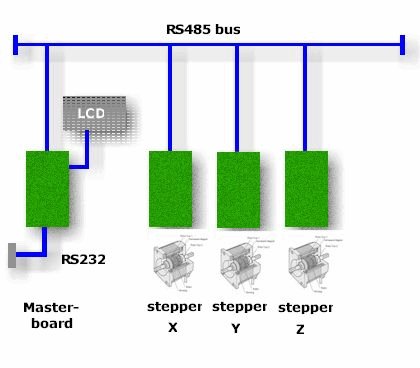

This document describes the construction of a PCB drill machine driven by a master-controller board and three stepper motor driver boards. These four single sided PC boards each contain an Atmega16/32 microcontroller. Communication between the boards is performed using the RS485 protocol with all communication initiated by the master-controller. The Atmega16/32 software is completely written in Bascom-AVR.

On the master-board a PS2-connector to connect a PS2-keyboard. Furthermore a 8 x 24 LCD. A RJ45-connector for the RS485-bus. A Max232 for serial communication. An Atmega32 is controlling all.

On the stepper motor driver board an Atmega16. A RJ45-connector for RS485-communication. A fan to keep the temperature of the drivers for the stepper motor at a reasonable level. A stepper motor driver-board is an autonomic device. It gets a command from the master-controller-board and it takes care of the stepper motor motion, error-detection and error-correction. The initiative of communication on the RS485 bus is at the master-controller-board. It submits the stepper motor commands and will wait until the commands are done.

RS485-connection. The initiative for communication is always done by the master-board. It sends the commands to the slaves and waits till the slave comes back with a READY or ERROR-message. Depending on the ERROR-code a resend of the command is done (slave sends an error-message because the checksum is not right), slave sends a READY when the command is finished.

For the design of printed circuit boards we have chosen Eagle. With Eagle’s CAM-processor an Excellon drill-file is generated. This Excellon file is presented to the Drill-machine and the Drill-machine will do his drilling from top to bottom of the file. We haven’t made any tool change equipment, but by running the Excellon file several times from top to bottom, we can use different drills. To monitor the RS485-communication-bus we added a small piece of electronics.

And now, with a communication program, like HyperTerminal, we can monitor all traffic on the RS485-communication-bus.

PCB drill machine

PCB drill machine electronic projects files: atmega32-pcb-drill-machine.RAR alternative link2 alternative link3

Read more information….