Introduction

The Utah State University (USU) Materials Physics Group (MPG) is interested in the performance

of Commercial Off the Shelf (COTS) microcontrollers in space conditions. Microcontrollers are commonly

used on CubeSats, small relatively inexpensive satellites that are flown in Low Earth Orbit (LEO) at

altitudes of ~160 km-2000 km. There is a large area of interest in COTS microcontrollers because they

provide a more cost-effective on-board computer for CubeSats. This experiment focused on the

functionality of an ATmega328 microcontroller on an Arduino Uno board inside the MPG’s Space

Survivability Test (SST) Chamber. A diagnostic program was used to try to detect radiation effects on the

microcontroller, including both soft errors and permanent failures. ArduSats is the coined term for CubeSats

that use Arduino boards for space flight [1]. Though ArduSats are typically used for educational purposes,

the results from this research and proposed related tests could shed light on a CubeSat’s (particularly an

ArduSat’s) ability to pursue extended space missions into more radiation intensive environments such as

Geosynchronous orbits and lunar missions.

Space Environment and Effects

The main component of space environments examined in this experiment was radiation exposure;

however, the test was performed in vacuum. Different orbits expose satellites to various levels and types

of radiation. The LEO dose level is about 2 krad/yr. This is relatively low compared to the Medium Earth

Orbit (MEO) (~100 krad/yr at 2000 km-35000km) and GEO (~50 krad/yr aboave 35000 km) [2]. These

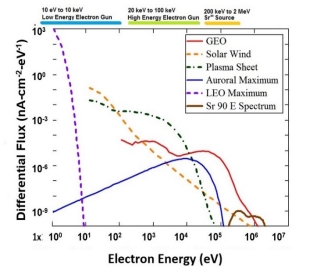

values could be assuming some minimal amount of shielding. As seen in Figure 1, some regions of space

have a high electron flux, such as LEO, but the energy of these electrons is relatively low. This means that

the microcontroller can be protected from a large portion of these electrons with very minimal shielding.

Microprocessors can experience failures ranging from soft errors to total system failure due to

radiation effects. A soft error, also known as a single-event

upset (SEU), is when radiation causes enough of a charge

disturbance to alter the state of a memory bit. These are called

space environments (Sr90 source is ~200keV-~2MeV) [3].

setup.

soft errors because they are repairable, and the system is still functional after an SEU. There are both

multibit upsets and single bit upsets, but the latter is more common [4]. A single-event effect (SEE) happens

when high-energy particles in the space environment strike the components of the microcontroller circuit

[5]. An SEE can cause a range of damage including, no observable effect, a transient disruption of circuit

operation, a change of logic state, or even permanent damage to the device or integrated circuit (IC) [5].

The microelectronic circuits in this experiment are particularly susceptible to radiation because of

their physical size. They are small enough that an energetic particle can change the device state or destroy

a trace. In some cases, these high-energy particles can even destroy portions of the microcontroller’s

memory . Beta radiation hits these circuits with electrons, causing the SEE’s. The long-term damage done

by radiation in space environments is typically due to the total ionizing dose (TID), which is the total

amount of radiation an object is exposed to.

Chamber Capabilities

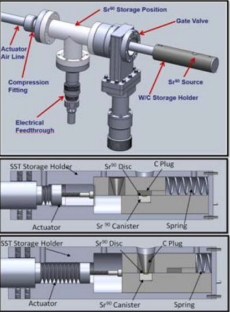

The SST chamber (Figure 2) contains ~100 mCi Sr90 beta radiation source (Figure 3) that provides

a dose rate of ~0.1 krad/hr at a 30 cm distance over a 15 cm diameter sample area [3]. This dose rate

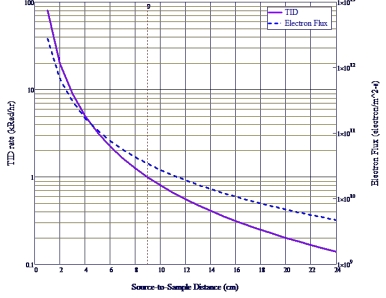

provides an upper bound approximation of the dosing rate in GEO with minimal shielding. To expedite the

testing process, the distance to the radiation source can be decreased; this relationship is shown in Figure

- Since the dose rate was only important as it related to the total ionizing dose (TID), the Arduino board

with dimensions of ~7cm x ~5.5 cm was moved to ~9 cm from the source, increasing the TID rate to ~0.991

krad/hr, but decreasing the diameter of a uniform dose to ~4.5 cm. The ATmega328 chip was centered

under the source since this experiment was focused on the microcontroller There are many instrumentation

cabling feedthroughs available on the SST chamber, including both USB and D-pin serial adapters, able to

accommodate a maximum voltage of 100 V and a maximum current of 1 A.

Cutaway views while in the (b) closed

and (c) exposure positions [3].

respectively

Microcontroller Design

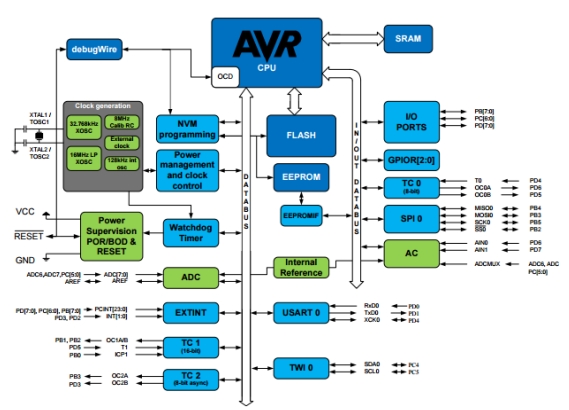

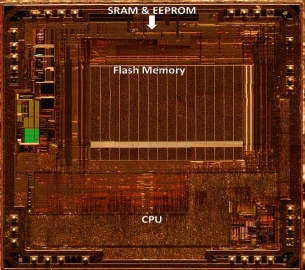

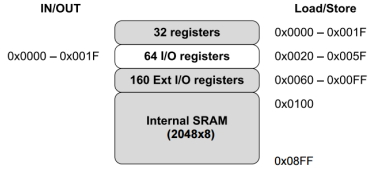

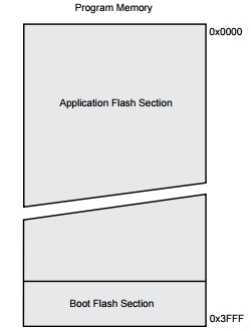

The microcontroller used in this experiment was an ATmega328 on the Arduino Uno development

board (Atmel, ATmega328/P). There are three types of memory associated with this microcontroller: Flash,

SRAM, and EEPROM (Table 1). As can be seen in Figures 5 and 6, the Flash memory is physically the

largest memory portion of the chip, which makes it the most susceptible of the three memory sections to

radiation damage. The Flash memory is where the program is uploaded and stored in the microcontroller.

This memory is divided into two physical regions: the Boot Loader and Application section [5]. The Boot

Loader section contains firmware that aids in programming the microcontroller when using the Arduino

Integrated Development Environment (IDE). This leaves the Application section to store any program that

is written to the microcontroller [6]. Flash memory is non-volatile memory which means the information

stored there remains even when the power is turned off. Static Random Access Memory or SRAM is the

portion of memory used by the program to create and manipulate variables. Unlike the Flash memory, the

SRAM is volatile memory, meaning that all information stored there is deleted every time the

microcontroller is turned off. Lastly, the electrically erasable programmable read-only memory (EEPROM) is dedicated space to save long-term information, making it non-volatile memory. Since there is a high volume of open source

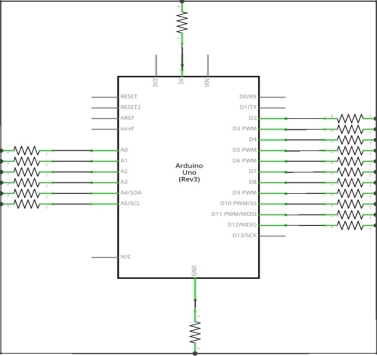

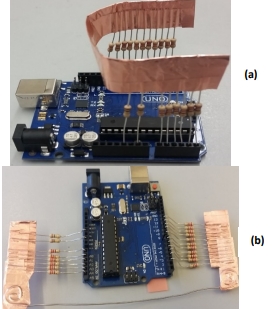

Arduino code on the internet, code was taken and modified for the purposes of this experiment. The

bulk of this code was left unchanged from what was found online. The original code was created by Terry King and can be found at arduinoinfo.wikispaces.com/Arduino_Test. The program used assumes that pins 0, 1, and 13 work if the

program can be uploaded and if the on-board LED can blink, therefore this program does not test these

pins. Digital pins 2-12 and analog pins A0-A5 each had 220 Ω resistors connected to each other in parallel.

These resistors were then connected in series to the 5-Volt power supply and the ground through 100 kΩ

resistors (see Figures 7 and 8). The circuit design created a voltage divider that provided each of the

common points with 2.5 V when the pins were set to high input. The code runs a total of three types of tests

to ensure that all the pins were functioning properly.

The first test uses the first analog pin (A0) to see if the common points are at anything besides 2.5

V, which would indicate that a pin was stuck in a High or Low state or is not properly set to either state.

The next type of test sets pins 3-A5 to the High or Low state and setting pin 2 to the opposite state. Each of the pins

are individually tested against pin 2 and must be able to sink or source the proper amount of current to pass the

test. The last type of test verifies that the analog pins read out the correct voltages when supplied with various

voltages. If any failures are detected by the program, they are then summed and a read out of how many failures

occurred during the test is displayed at the end of the print out. A delay function is at the end of the code to

allow the user to run the code at whatever the desired frequency is. This program takes ~2 seconds to run

through all the tests and output the data. This code is named King_Olsen_Diagnostics.ino and can

be found in the raw data compressed file given separately.

The Arduino IDE was the code writing environmentused in this project. Although Arduino IDE allows programs to output data to the Serial Monitor, the output is not archived anywhere. Therefore, the only way to save information from the Serial Monitor is to copy and paste the output into a text file once data is acquired. This is not the most reliable way to save the data because if the Serial Monitor is closed for any reason during the test, all that data is lost. Therefore, the Serial Monitor was only used for quick checks to ensure that the program was

performing properly and another program called CoolTerm from www.freeware.the-meiers.org was used to save the data. CoolTerm allowed for the user to record the data to a text file and monitor the program at the same time. Another necessary feature for archiving the data was parallel serial monitoring. The Arduino IDE only allows for one Serial Monitor window to be open at a time while CoolTerm allowed the user to run, watch, and save data from two different setups at once. This feature was important because while an Arduino was being tested in the chamber (referred to as the “test Arduino”), an identical setup was being tested outside the chamber without

radiation exposure (referred to as the “control Arduino”) and both of their data needed to be recorded. The control Arduino provided information about how the microcontroller performed of an extended period without radiation

exposure. CoolTerm also allowed all of the data to be timestamped as it was being saved into a text

document.

How frequently the diagnostic code is running is directly related to the probability of recording a

soft error. As previously mentioned, SEU’s are temporary failures in the system being tested, which makes

them more difficult to test. Simply taking more data helps in the detection of these soft errors. If the test is

running less frequently, then the SEU could occur and the affected bit could go back to normal before the

program is run again. The program was set to run every fifteen minutes and it took 2 seconds to complete.

Therefore, the Arduino was only being tested 8 secs/hr or 1/450 of the testing duration.

(b) Chamber setup

Testing

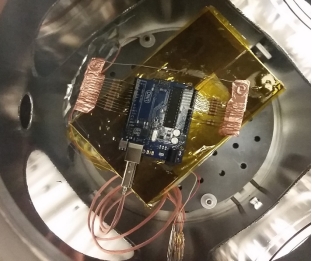

The chamber Arduino was placed on top of a large beaker with a piece of Kapton-insulated graphite

inside the SST Chamber (Figure 9) to increase the TID rate to ~1 krad/hr. Because the main objective was

to test the microcontroller, the Arduino was positioned so the ATmega328 chip was centered under the

radiation source. The Arduino communicated with the computer via a ~58 cm USB type B cable (Figure

10) designed for this experiment. The high vacuum compatible cable was made of four Kapton-insulated

wires that were braided into two wire pairs to minimize ground loop noise and put inside a coaxial copper

braided sleeve. The end of the cable opposite to the Arduino had pins sockets that connected to the vacuum

electrical feedthrough pins inside the chamber. On the outside of the chamber, a ~185 cm standard USB

type A cable with four pins was connected to the computer and the corresponding pins on the outside

vacuum electrical feedthroughs.

The diagnostic code was tested with a 1 second delay while the vacuum chamber pumped down to

a pressure of ~1.7×10-7 torr and the radiation source was not in place. The delay was then changed to 10

seconds with the closed source inserted into the chamber. The source was then opened and the Arduino was

chamber.

sockets used for the cabling feedthrough.

monitored in this configuration for 35 minutes. Finally, the delay was set to run once every 15 minutes, to

keep the amount of data to a reasonable amount, presumably until a failure was observed. A control Arduino

outside the chamber followed these same configurations for the entirety of the test.

Results

After ~188 hours of exposure (~186 krads), the diagnostic code had not detected any pin failures

while running in 15 minute intervals. In an attempt to detect SEU’s, it was proposed to reupload the program

with a shorter delay. The 15 minute delay was replaced with a 10 second delay. However, when trying to

upload the adjusted code, an error message was produced. This error message read “avrdude: verification error,

first mismatch at byte 0x133f 0xea != 0xe6; avrdude: verification error; content mismatch; avrdude: verification error; content mismatch”. An error such as this indicates an issue in either the memory or communications with the computer. The same error message was produced with each attempt at uploading any sort of code

to the test Arduino. Also, the diagnostic code was successfully uploaded to a third Arduino. These exercises ruled out a

communications issue, leaving a failure in the memory. The location of the mismatched byte is given in the message as

0x133f, 4927 in decimal. From examining the memory maps of

memory [6].

the SRAM (Figure 11) and the Flash memory (Figure 12), the location of this error can be narrowed down

even further. SRAM contains addresses ranging from 0x0000-0x08ff, 0-2303. This range is not large

enough to contain the location of the problem byte. Flash memory contains addresses from 0x0000-0x3fff,

0-16383. The EEPROM is left for the user to store data, so a program does not use this memory unless it is

written into the code, which was not the case for this program. Therefore, the mismatched byte must be in

the Flash memory. It makes sense that an error would occur here because of the physical size of the flash

memory. The portion of the error message that says “0xea != 0xe6” is indicating that the bootloader found

binary 1110 1010 instead of 1110 0110. This means that two bits are in the wrong state. Since the error was

identical every time the program was uploaded, it can be assumed that these bits were permanently stuck

in the wrong state.

The program continued to run a diagnostic test at 15 minute intervals until the Arduino stopped

writing to the computer after ~263 hours (~260 krads). The diagnostic program did not show a single pin

failure throughout the entire test, however errors did occur.

Conclusions & Future Work

In conclusion, the diagnostics program never indicated pin failures although the TID from this test

was on the same order of magnitude of the TID during a year in MEO. However, an error did arise when

trying to upload code to the Arduino after ~186 krads of exposure. This error was caused by two bits in the

Flash memory being stuck in the wrong state. Also, the Arduino stopped writing to the computer after being

exposed to ~260 krads. Although the pins seemed to still be operational in the MEO and GEO ranges, the

memory was affected and further investigation into the consequences of these effects would be pertinent to

CubeSat flights.

Source: Microcontroller Survivability in Space Conditions