Abstract

Introduction

Environmental sensors, encompassing parameters like temperature, humidity, smoke, gases, solar radiation, and pressure, find application in both indoor and outdoor settings. Some sensors specialize in monitoring specific elements such as CO2, O2, and H2. Typically, these sensor networks function as short-distance data transmitters, characterized by low power consumption and cost-effectiveness.

Several factors, including deployment activities, indoor/outdoor locations, and the specific application data to be processed and inferred, influence the structures of these sensors and their platforms. With ongoing technological advancements, a new type of environmental monitoring system has emerged, leveraging Zigbee technology. This system harnesses the wireless sensor network capabilities and mature communication technologies of Zigbee, facilitating real-time monitoring and intelligent warnings for environmental and production parameters.

At its core, this system is equipped with a low-power AVR processor chip (ATmega32) and Zigbee as the communication platform for wireless sensor networks. Extensive testing has validated the system’s design feasibility and stability, confirming its potential for monitoring and control applications with smart sensor nodes.

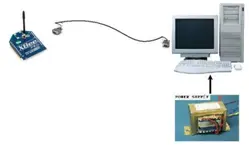

The Zigbee-based temperature and humidity acquisition system involves a device comprising a sensor and a microcontroller transmitting climatic parameters wirelessly to a receiver using Zigbee communication. An accompanying Zigbee control application allows for data acquisition, display, and configuration. Temperature readings from sensors, connected to the AVR-based microcontroller via Analog to Digital Converter, are sent to a PC through Zigbee transmitters. This wireless sensor network serves as a valuable solution in scenarios where traditional installations are challenging due to factors like lack of power access or connectivity issues.

The advantages of employing a wireless network in this context include energy efficiency, absence of hardwiring requirements, and extended transmission distances. This research exploits the benefits of wireless sensor networks for weather monitoring stations, where sensor stations measure and transmit parameters through a wireless network server.

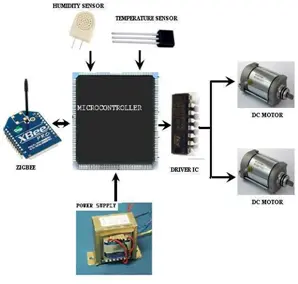

Block Diagram

– Microcontroller: AVR Atmega32

– Communication Modules: Zigbee

– Serial Communication Interface: Max232

– Environmental Sensors: Temperature Sensor, Humidity Sensor

– Output Display: LCD Display

– Power Source: Power Supply

Introduction to AVR Atmega32

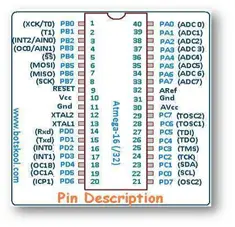

The Atmega32 stands out as a low-power CMOS 8-bit microcontroller built upon the AVR enhanced RISC architecture. Its efficiency lies in the execution of potent instructions within a single clock cycle, enabling throughputs nearing 1 MIPS per MHz. This approach allows for system designs that effectively balance power consumption and processing speed.

The AVR core of the Atmega32 integrates a diverse instruction set with 32 general-purpose working registers. These registers directly link to the Arithmetic Logic Unit (ALU), enabling the simultaneous access of two independent registers in a single instruction executed within a single clock cycle. This architectural choice enhances code efficiency, achieving throughputs up to ten times faster than conventional CISC microcontrollers.

Key features of the Atmega32 include 8K bytes of In-System Programmable Flash Program memory with Read-While-Write capabilities, 1024 bytes of EEPROM, 2K bytes of SRAM, 32 general-purpose I/O lines, and a JTAG interface for Boundary scan. Additionally, it offers on-chip debugging support and programming, three flexible Timer/Counters with compare modes, internal and external interrupts, a serial programmable USART, a byte-oriented Two-wire Serial Interface, and an 8-channel, 10-bit ADC with an optional differential input stage with programmable gain (TQFP package only).

The microcontroller further supports a programmable Watchdog Timer with an internal oscillator, an SPI serial port, and six software-selectable power-saving modes. The Idle mode halts the CPU while permitting the continued functioning of various peripherals. Power-down mode conserves register contents but freezes the oscillator until the next External Interrupt or Hardware Reset. Power-save mode allows the asynchronous timer to persist while other functions sleep. The ADC Noise Reduction mode minimizes switching noise during ADC conversions by stopping the CPU and all I/O modules except the Asynchronous Timer and ADC. Standby mode keeps the crystal/resonator oscillator running while the rest of the device sleeps, facilitating a quick startup with low-power consumption. Extended Standby mode maintains the operation of both the main oscillator and the Asynchronous Timer.

Zigbee Operation

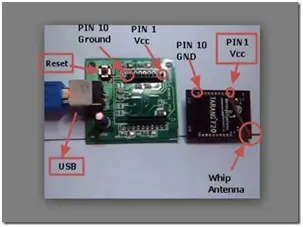

The Zigbee boards [5] utilize a V2 XBEE module to connect with the Zigbee network, adhering to the 2007 Zigbee Pro / ZNET standard. The V2 XBEE modules are available in two types: one configured as the Zigbee network coordinator (EB051C), and the other configured as either a router node or an end device node (EB051R). The module’s type is indicated at the top right-hand side of the Zigbee board.

Coordinator nodes play the crucial role of establishing the Zigbee network and facilitating the joining of other Zigbee nodes. Only one coordinator node is allowed on a single network. Router nodes are responsible for routing signals to other routers or end nodes, while end device nodes handle the collection or transmission of real-world data to and from the Zigbee network. Both the coordinator node and router nodes can manage up to eight children devices, comprising other router nodes or end device nodes. In the case of an end device node configured to sleep, the associated parent device becomes responsible for buffering incoming data. Hence, for sleeping end devices, it is essential to poll the parent for data each time the device exits sleep mode.

The board is compatible with both 3.3V and 5V systems.

Communications

The XBEE modules [4] utilize a TTL level RS232 bus for configuring by sending and receiving AT commands. This protocol necessitates a start bit, eight data bits, and a stop bit. The XBEEmodule’s baud rate is set to 9600, with no parity, and it includes flow control lines RTS and CTS that can be employed. AT commands are strings of ASCII data transmitted over the RS232 bus. For detailed information on the AT commands utilized by the XBEE module, please consult the V2 XBEE datasheet. An illustrative AT command is ATID 234, which assigns a personal area network identifier of 0x234 or 564 in decimal.

Zigbee is a wireless network protocol expressly crafted for low-rate sensor and control networks. In comparison to alternative wireless protocols, Zigbee offers low complexity, reduced resource requirements, and, significantly, adheres to a standard set of specifications. Additionally, Zigbee provides three frequency bands of operation and various network configurations, along with optional security capabilities.

Interface and Operation

The Tarang modules establish connectivity with a host device via a logic-level asynchronous serial port. Through its serial interface, the module is capable of communicating with any UART that is both logic and voltage compatible, or alternatively, through a level translator, with any serial device such as an RS-232 or USB interface board.

Serial Interface:

Tarang can be connected to a microcontroller or a PC using a serial port, where CTS and RTS are optional (refer to pin configuration for details). Tarang supports serial data with the following specifications:

– Flow Control: Hardware, None

– Parity: None

– Baud Rates: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

– Data Bits: 8

For successful serial communication with the module, it is crucial to configure the serial parameters correctly on both the module and host sides. Both the module and PC settings can be viewed and adjusted using the AT command set through popular terminal applications like ‘HyperTerminal.’

5. Combustible Smoke Sensors

Features

– Straightforward analog output

– High sensitivity to LPG, iso-butane, propane

– Limited sensitivity to alcohol and smoke

– Rapid response

– Broad detection range

– Consistent performance and extended lifespan

Resultsand Discussion

This study explores an innovative method for capturing temperature, smoke, and humidity signals employing cost-effective, low-power components. The acquired data is transmitted to a central monitoring base station through a Zigbee communication system. A dedicated application was developed for the central data collection station to acquire and store temperature and humidity values. The system’s performance was assessed through laboratory tests utilizing a climate chamber to simulate environmental conditions. The results demonstrate that the device accurately tracks the environmental conditions created by the climatic chamber. Furthermore, the application for the base station effectively acquires and stores data transmitted by the apparatus through the Zigbee connection acting as a transceiver. This approach proves valuable for monitoring climate conditions in smaller settings such as laboratories and classrooms.

The system can be applied in medical environments, among others, to activate alarms in response to changes in conditions or when certain fixed thresholds are surpassed. Another potential use of this system is the identification of fire in confined spaces.

Future Scope

– Data acquisition is possible on a smartphone in conjunction with base stations.

– Industrial parameter monitoring can utilize a variety of other industrial sensors [6].

– The application of this project extends to the domestic agricultural sector. In civilian applications, future developments can facilitate accurate irrigation in farm fields by assessing the soil moisture level in specific areas.