Pulse Width Modulation (PWM) is a very common technique in telecommunication and power control. it is commonly used to control the power fed to an electrical device, whether it is a motor, an LED, speakers, etc. It is basically a modulationtechnique, in which the width of the carrier pulse is varied in accordance with the analog message signal.

We make simple electrical circuit to control rotational speed of the DC motor in light intensity dependent. We are going to use Light Dependent Resistor and AVR microcontroller features such as Analog to Digital Conversion to measure the light intensity. Also we are going to use Dual H-Bridge Motor Driver Module-L298N. It is typically used in controlling motors speed and direction, but can be used for other projects such as driving the brightness of certain lighting projects. Also, added a button to our circuit to toggle the direction of rotation of the engine.

Step 1: Description

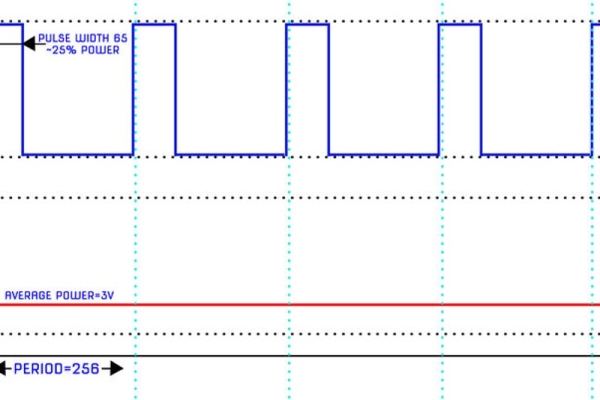

Each and every body in this world has some inertia. The motor rotates whenever it is powered on. As soon as it is powered off, it will tend to stop. But it doesn’t stop immediately, it takes some time. But before it stops completely, it is powered on again! Thus it starts to move. But even now, it takes some time to reach its full speed. But before it happens, it is powered off, and so on. Thus, the overall effect of this action is that the motor rotates continuously, but at a lower speed.

Pulse Width Modulation (PWM) is a comparatively recent power switching technique for providing intermediate amounts of electrical power between fully on and fully off levels. Usually, digital pulses have same on and off time period, but in some situations we need the digital pulse to have more/less on time/offtime. In PWM technique, we create digital pulses with unequal amount of on and off state to get required intermediate voltage values.

Duty cycle is defined by the percentage of high voltage duration in a complete digital pulse. It can be calculated by:

% of Duty cycle = T on /T (period time) x 100

Let us take a problem statement. We need to generate a 50 Hz PWM signal having 45% duty cycle.

Frequency = 50 Hz

Time period, T = T(on) + T(off) = 1/50 = 0.02 s = 20 ms

Duty Cycle = 45%

Thus, solving according to equation given above, we get

T(on) = 9 ms

T(off) = 11 ms

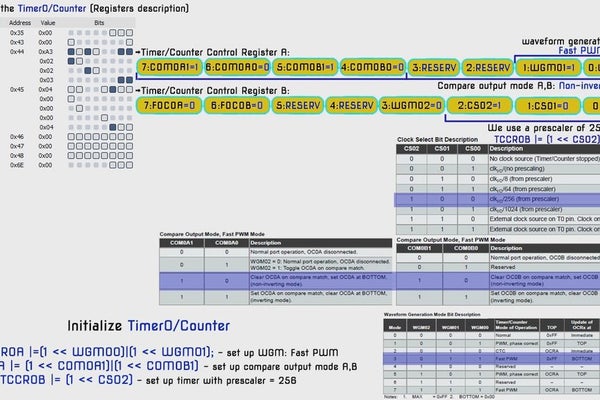

Step 2: AVR Timers – PWM Mode

For making PWM, AVR contains separate hardware! By using this, the CPU instructs the hardware to produce PWM of a particular duty cycle. The ATmega328 has 6 PWM outputs, 2 are located on timer/counter0 (8bit), 2 are located on timer/counter1 (16bit), and 2 is located on timer/counter2 (8bit). Timer/Counter0 is the simplest PWM device on the ATmega328. Timer/Counter0 is capable of running on 3 modes:

- Fast PWM

- Phase and Frequency Corrected PWM

- Phase Corrected PWM

each of these modes can be inverted or non-inverted.

Initialize Timer0 in PWM mode:

TCCR0A |=(1 << WGM00)|(1 << WGM01) – set up WGM: Fast PWM

TCCR0A |= (1 << COM0A1)|(1 << COM0B1) – set up compare output mode A,B

TCCR0B |= (1 << CS02) – set up timer with prescaler = 256

Step 3: Light Intensity Measurement – ADC & LDR.

Light Dependent Resistor (LDR) is a transducer which changes its resistance when light falls on its surface changes.

LDRs are made from semiconductor materials to enable them to have their light sensitive properties. These LDRs or PHOTO RESISTORS work on the principle of “Photo Conductivity”. Now what this principle says is whenever light falls on the surface of the LDR (in this case) the conductance of the element increases or in other words the resistance of the LDR decreases when the light falls on the surface of the LDR. This property of the decrease in resistance for the LDR is achieved because it is a property of semiconductor material used on the surface. LDR are used most of times to detect presence of light or for measuring the intensity of light.

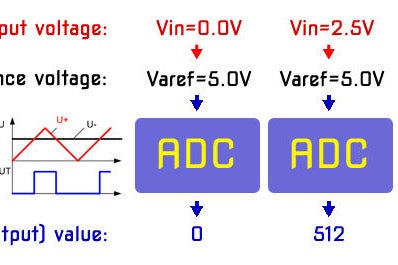

For transferring external continuous information (analog information) into a digital/computing system, we must convert them into integer (digital) values. This type of conversion is carried out by Analog to Digital Converter (ADC). The process of converting an analog value into digital value is known as Analog to Digital Conversion. In short, Analog signals are real world signals around us like sound and light.

Digital signals are analog equivalents in digital or numeric format which are well understood by digital systems like microcontrollers. ADC is one such hardware which measures analog signals and produces a digital equivalent of the same signal. AVR microcontrollers has inbuilt ADC facility to convert analog voltage into an integer. AVR convert it into 10-bit number of range 0 to 1023.

We use analog to digital convert of voltage level from divider circuit with LDR to measure the light intensity.

Initialize ADC:

TADCSRA |= (1<<ADEN) – Enable ADC

ADCSRA |= (1<<ADPS2)| (1<<ADPS1)| (1ADPS0) – set up ADC prescaler = 128

ADMUX = (1 << REFS0) – set up voltage referance = AVCC; – set up Input Channel = ADC0

Watch the video with a detailed description of the ADC AVR microcontroller: AVR Microcontroller. Light Intensity Measurement. ADC & LDR

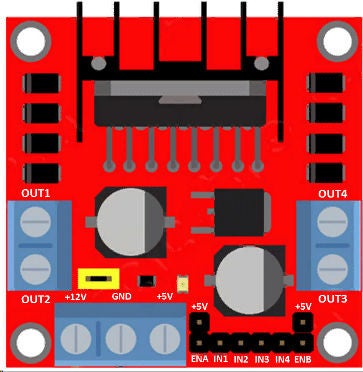

Step 4: Controller DC Motor & Dual H-Bridge Motor Driver Module-L298N

We use DC motor drivers because microcontrollers are not capable of delivering current not more than 100 milliamps in general. The microcontrollers are smart but not strong; this module will add some muscles to microcontrollers to drive high power DC motors. It can control 2 DC motors simultaneously up to 2 amps each or one stepper motor. We can control the speed using PWM and also its rotational direction of the motors. Also, It used for driving the brightness of LED tape.

Pin description:

OUT1 and OUT2 port, which is for connecting DC motor. OUT3 and OUT4 for connecting LED tape.

ENA and ENB are enable pins: by connecting ENA to high(+5V) it enables the port OUT1 and OUT2.

If you connect the ENA pin to low(GND), it disables the OUT1 and OUT2. Similarly, for ENB and OUT3 and OUT4.

IN1 to IN4 are the input pins which will be connected to AVR.

If IN1-high(+5V), IN2-low(GND), the OUT1 turns high and OUT2 turns low, thus we can drive motor.

If IN3-high(+5V), IN4-low(GND), the OUT4 turns high and OUT3 turns low, thus LED tape light is on.

If you want to reverse the rotational direction of the motor just reverse IN1 and IN2 polarity, similarly for IN3 and IN4.

By applying PWM signal to ENA and ENB you can control the speed of the motors on two different output ports.

The board can accept from 7V to 12V nominally.

Jumpers:There are three jumper pins; Jumper 1: If you’re motor need more than 12V supply you have to disconnect the Jumper 1 and apply desired voltage (max 35V) at 12V terminal. Bring another 5V supply and input at 5V terminal. Yes, you have to input 5V if you need to apply more than 12V (when Jumper 1 is removed).

The 5V input is for proper functioning of the IC, since removing the jumper will disable the in-built 5V regulator and protect from higher input voltage from 12V terminal.

The 5V terminal acts as output if your supply is between 7V to 12V and acts as input

if you apply more than 12V and jumper is removed.

Jumper 2 and Jumper 3: If you remove these two jumpers you have to input the enable and disable signal from the microcontroller, most of the users prefer removing the two jumpers and applying the signal from microcontroller.

If you keep the two jumpers the OUT1 to OUT4 will be always enabled. Remember ENA jumper for OUT1 and OUT2. ENB jumper for OUT3 and OUT4.

Step 5: Writing Code for a Program in C. Uploading HEX File Into the Microcontroller Flash Memory

Writing and building the AVR microcontroller application in C Code using the Integrated Development Platform – Atmel Studio.

#ifndef F_CPU

#define F_CPU 16000000UL // telling controller crystal frequency (16 MHz AVR ATMega328P) #endif#include //header to enable data flow control over pins. Defines pins, ports, etc. #include //header to enable delay function in program#define BUTTON1 2 // button switch connected to port B pin 2 #define DEBOUNCE_TIME 25 // time to wait while "de-bouncing" button #define LOCK_INPUT_TIME 300 // time to wait after a button press// Timer0, PWM Initialization void timer0_init() { // set up timer OC0A,OC0B pin in toggle mode and CTC mode TCCR0A |= (1 << COM0A1)|(1 << COM0B1)|(1 << WGM00)|(1 << WGM01); // set up timer with prescaler = 256 TCCR0B |= (1 << CS02); // initialize counter TCNT0 = 0; // initialize compare value OCR0A = 0; }// ADC Initialization void ADC_init() { // Enable ADC, sampling freq=osc_freq/128 set prescaler to max value, 128 ADCSRA |= (1<<ADEN) | (1<<ADPS2)| (1<< ADPS1)| (1<<ADPS0); ADMUX = (1<<REFS0); // Select Voltage Reference (AVCC)// Button switch status unsigned char button_state() {/* the button is pressed when BUTTON1 bit is clear */ if (!(PINB & (1<<BUTTON1))){_delay_ms(DEBOUNCE_TIME);if (!(PINB & (1<<BUTTON1))) return 1;} return 0;}// Ports Initialization void port_init() { DDRB =0b00011011; //PB0-IN1, PB1-IN2,PB3-IN3, PB4-IN4, PB2 - BUTTON SWITCH DIRECT PORTB=0b00010110; DDRD =0b01100000; //PD5-ENB (OC0B), PD6-ENA (OC0A) PORTD=0b00000000; DDRC =0b00000000; // PC0-ADC PORTC=0b00000000; // Set all pins of PORTC low which turns it off. }// This function reads the value of the analog to digital convert. uint16_t get_LightLevel() { _delay_ms(10); // Wait for some time for the channel to get selected ADCSRA |= (1<<ADSC); // Start the ADC conversion by setting ADSC bit. Write 1 to ADSC while(ADCSRA & (1<<ADSC)); // Wait for conversion to complete // ADSC becomes 0 again till then, run loop continuously _delay_ms(10); return(ADC); // Return the 10-bit result}// This function Re-maps a number from one range (0-1023) to another (0-100). uint32_t map(uint32_t x, uint32_t in_min, uint32_t in_max, uint32_t out_min, uint32_t out_max) { return (x - in_min) * (out_max - out_min) / (in_max - in_min) + out_min; }int main(void) { uint16_t i1=0; port_init(); timer0_init(); ADC_init(); // initialization ADC while (1) { i1=map(get_LightLevel(),0,1023,0,100); OCR0A=i1; // Set output compare register channel A OCR0B=100-i1; // Set output compare register channel B (inverted) if (button_state()) // If the button is pressed, toggle the LED's state and delay for 300ms (#define LOCK_INPUT_TIME) { PORTB ^= (1<<0); // toggling the current state of the pin IN1. PORTB ^= (1<<1); // toggling the current state of the pin IN2. Reverse the rotational direction of the motor PORTB ^= (1<<3); // toggling the current state of the pin IN3. PORTB ^= (1<<4); // toggling the current state of the pin IN4. LED Tape is turn off/on. _delay_ms(LOCK_INPUT_TIME); } }; return (0); }

Programming is complete. Next, building and compiling project code into hex file.

Uploading HEX file into the microcontroller flash memory:

type in DOS prompt window the command:

avrdude –c [name of programmer] –p m328p –u –U flash:w:[name of your hex file]

In my case it is:

avrdude –c ISPProgv1 –p m328p –u –U flash:w:PWM.hex

This command writes hex file to the microcontroller’s memory. Watch the video with a detailed description of the microcontroller flash memory burning: Microcontroller flash memory burning…

Ok! Now, the microcontroller works in accordance with the instructions of our program. Let’s check it out!

Source: AVR Microcontroller. Pulse Width Modulation. Сontroller of DC Motor and LED Light Intensity.