New approach harnesses the same fabrication processes used for silicon chips, offers key advance toward next-generation computers. by Rob Matheson | MIT News Office

After years of tackling numerous design and manufacturing challenges, MIT researchers have built a modern microprocessor from carbon nanotube transistors, which are widely seen as a faster, greener alternative to their traditional silicon counterparts.

The microprocessor, described today in the journal Nature, can be built using traditional silicon-chip fabrication processes, representing a major step toward making carbon nanotube microprocessors more practical.

Silicon transistors — critical microprocessor components that switch between 1 and 0 bits to carry out computations — have carried the computer industry for decades. As predicted by Moore’s Law, industry has been able to shrink down and cram more transistors onto chips every couple of years to help carry out increasingly complex computations. But experts now foresee a time when silicon transistors will stop shrinking, and become increasingly inefficient.

Making carbon nanotube field-effect transistors (CNFET) has become a major goal for building next-generation computers. Research indicates CNFETs have properties that promise around 10 times the energy efficiency and far greater speeds compared to silicon. But when fabricated at scale, the transistors often come with many defects that affect performance, so they remain impractical.

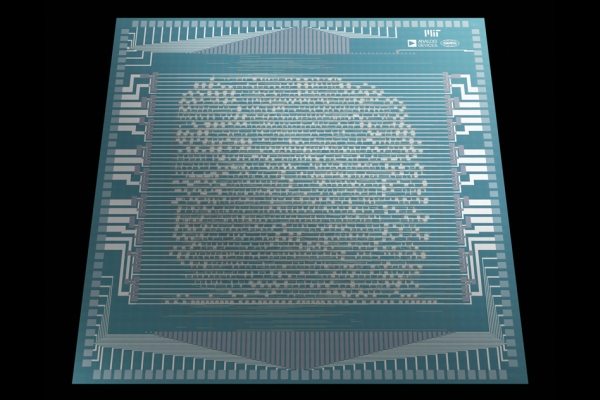

The MIT researchers have invented new techniques to dramatically limit defects and enable full functional control in fabricating CNFETs, using processes in traditional silicon chip foundries. They demonstrated a 16-bit microprocessor with more than 14,000 CNFETs that performs the same tasks as commercial microprocessors. The Nature paper describes the microprocessor design and includes more than 70 pages detailing the manufacturing methodology.

Read more: MIT ENGINEERS BUILD ADVANCED MICROPROCESSOR OUT OF CARBON NANOTUBES