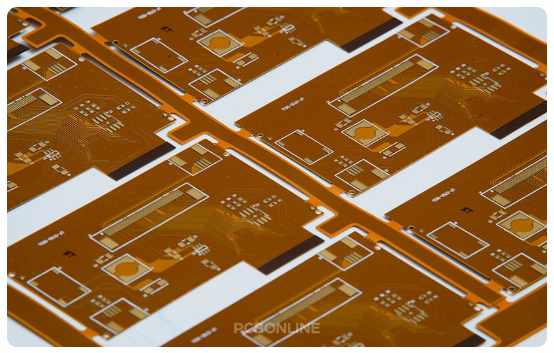

The F lexible P rinted C ircuit B oards are also known as ( FPCB ) or flex circuits. They are initially designed to replace the original wire connections. The difference between the ordinary PCB and FPCB can be found in their end-design, functionality, and fabrication.

The flexible printed circuit boards have their own manufacturing rules and most of the producers are making a common mistake, designing them using the same rules as a PCB.

The FPCB contains a metallic layer that is commonly made of copper connected to a polyimide dielectric layer. In fact, the metal layer of flexible PCBs can be very thin. In order for the metal to be bonded to the substrate, an adhesive is commonly used.

There is, however, a protective layer from solder or gold that is covering the copper layer. They are the most common materials for covering the exposed surfaces because of their environmental durability and conductivity. On the other hand, a dielectric material is used to protect the non-contact areas from electrical shorting and oxidation.

There is a variety of material combinations that are used in the flexible printed circuit boards . In order to acquire a better understanding and visualize an FPCB, we will briefly go over some common models with standard materials.

Common Types of Flexible Printed Circuits

• Single-Sided Flexible Circuit

This is the most basic single layer flex circuit that is laminated in a thin surface of copper. A chemical etching is applied to the copper layer, in order to produce a specific pattern accordingly to the requested design. For environmental protection and insolation, a polyimide overlay is later added to the circuit.

• Double-Sided Flexible Circuit

Whenever a flex circuit has two conductive layers, it is called double-sided. The interesting thing here is that traces can be created on both sides, specifically for customer requirements. Sides can be connected whenever needed by holes in the copper plate. They are famous for the connection between the layers.

• Multi-Layer Flexible Circuit

This is the circuit where the combination of several single and double-sided circuits happens. They are a great solution where manufacturers are facing major issues with the circuits with fewer layers. Many individual requirements can be easily handled by the multi-layer circuit design.

• Rigid Flexible Circuit

Rigid-flex circuits can be four, six, or eight-layered. They are mainly used in the aerospace and military field of work, for more than 20 years now. Basically, they are the structure of multiple flexible circuit inner layers, connected together with an epoxy bonding. They combine the best of both flexible and rigid boards, integrated into a single circuit design.

The Benefits of Flexible Printed Circuits

There are a variety of benefits that are coming with the flexible circuit design. We will briefly go over some of the proven benefits and advantages that come with a flexible design.

• Capabilities – The flexible circuit is compatible with a large number of different components and connectors and more specifically they work great with ZIP connectors. They are also great under high temperatures and offer extreme resistance to chemicals and radiation.• Reliability – In general, the flexible printed circuit boards require fewer contact crimps and basically fewer interconnects in their design. That means that fewer connecters and solder joints are used. This

way there are fewer possible sources that can cause failure, and this is why they are considered significantly more reliable than the ordinary printed circuits.

• Optimized Spacing – The curious thing, and almost unbelievable is that the flexible circuits are using only around 10% to 15% of the space that the ordinary circuit boards are using. The same goes for weight also. They are offering great freedom regarding installation and space management. This is why many manufacturers are preferring a flexible circuit over the ordinary boards to use instead if it fits according to their needs.

• Price – There are a lot of cost-saving advantages and benefits when it comes to flexible printed circuits. If we take under consideration the fact that fewer materials are used and that the replacement cost is reduced due to the fewer assembly errors that can appear.

• Flexibility Installation – Third dimension flexibility is ideal to work with. They solve many space and weight problems that are common to occur with the installation of the regular circuits.

• Improved Airflow – Their complex flexible design is allowing a cooling airflow through the installation.

• High Density – The flexible circuits are allowing high-density device construction. They are freeing additional space for more features and create the ideal environment for improvements.

• Heat Dissipation – The compact design and the larger surface allow a shorter thermal path. The thinner design of the flexible circuits is providing heat dissipation for both sides.

• Wire Replacement – It is dependant on the number of point-to-point connections in the printed circuit design. Manufacturers, on the other hand, are guaranteeing that they can eliminate many, if not all of the interconnections by adding additional connectors. There is no information regarding the limit of the point-to-point connectors that the manufacturers can add as per their claims.

Design Options for Flexible Printed Circuits

Rigid-flex – Also called “ Hybrid hardboard ” or “ flex circuits ” the Rigid-flex circuits can have up to sixteen layers. They are a great replacement for the old wire connection with a compact and robust design.

Assembly Pallet – The final design product is held by frames of stiffener material in order to stay flat during the manufacturing process. It is providing the ability to just clip it out and proceed with the installation.

Surface Mount – For better and high-density packaging and installation compatibility the surface mount circuits are combining the space, as a result, they offer weight saving.

Pins – The pins can serve as extensions to the conductors. The solder pins are brazed to the circuit through holes.

Connectors – They create a seal between the connector and the circuit. It is an optimal solution for speed during the assembly process.

Shielding – Whenever this type of end-design is used, patterned or solid shield planes are reducing the noise and controlling the signal lines. The shielding design is commonly used for high-speed signal integrity.

Bonding – A selective binding is used for better flexibility and circuit arms. Each individual layer is unbonded offering freedom when it comes to managing space and complex placement spaces. Each layer has its own cover and substrate.

Flexible Circuit Technology Applications

Flexible circuits are a fast-growing technology in the field of electrical connectivity and they provide users with performance and flexibility for more than forty years now. Their compact and flexible design finds application in many industries and manufacturers are slowly turning their attention to the FPCB as they are proven to provide essential benefits and advantages. We will now review some of the common applications for flexible circuit technologies.

Automotive Industrial Cluster

For over twenty-five years the FPCB finds application in the automotive, delivering power and connectivity to the instruments mainly mounted in vehicle dashboards. You can easily observe their implementation also in the lightning, sensors, power, and many touch surfaces. When it all started, the circuits were only single-sided and low complexity. However, in modern times within the vehicles are applied many different designs of the flexible circuit improving the electronic nerve in general. With the growth of the electronics in vehicles, a great opportunity for the FPCB is arising. Nowadays, flexible printed

technology has improved all the electronic equipment, airbags, ABS, and many engine management tools that require the application of flexible interconnects.

For reference check the image below in order to acquire a better understanding of how many automotive parts are using the FPCBs.

The industry adopted the flexible technology due to its low cost and perfect functionality under high pressure and aggressive temperature. There is also a chemical and high level of dirt, which the flexible printed circuits can handle. It is considered as a key for reducing the complexity of the modern design in the scope of automotive. The industry overcame many assembly errors and limitations with the integration of flexible circuits in the process of assembly.

Telecommunications

For many years now the telephone headsets have utilized the flexible design of the printed circuits. The advantages that the industry was attracted to were the low cost and the well suited reliable circuit technology.

The flexible technology can be found in a variety of telecommunication equipment from automated switchboards to fax machines. The FPC is offering significant space-saving and management, and with the multilayered circuits comes a great degree of connectivity.

Many technical problems in mobile phones were solved with the implementation of flexible circuits. With that large improvement, the technology took a step further in the custom design demands. One of the first and in fact the initial application of flexible circuits in mobile phones was in touch-pads. The physical buttons were replaced with the backlit pliable dom buttons and polyester flex circuit that is combining the attraction of low cost and transparency.

With the demand for more inputs and outputs, the implementation of flex circuits came in the LCD screens of mobile phones. Once again the manufacturers improved reliability, lowered the assembly complexity and cost, by directly locating the components onto the flex surface.

In general, the flexible printed circuits are designed to overcome major challenges face the electronic field in the industry. They have become an essential part of the design of many electronic communication devices. They can maximize the efficiency of the signal and keep radiation away from the user at the same time.

The design approach in the flexible circuits demands production techniques that are different in comparison with the regularly printed circuit boards. It requires a process of combining electrical disciplines and mechanical touch to produce the end-design product.

For customers, it is essential to pay close attention and consider all of the relevant options that they have in order to achieve and acquire the result they want and avoid any further problems at the same time.

Flexible Printed Circuits at PCBONLINE

PCBONLINE is a great source to learn, order, and customize your own design as per your requirements. They provide real-time feedback with professional opinions and quotes, PCB fabrication, assembly, and components sourcing.

In PCBONLINE , they use a high-quality management system for every raw material and electronic component. They are using only reliable and proven sources for ensuring the reliability of your terminal products. They always aim to exceed your expectations by taking the advantages one step further in your service.

When working with them you can expect:

1. High-quality flexible PCB raw materials, ensuring the source quality.

Cover Film : TaiFlex, APLUS, RCCT

Material : Dupont, TaiFlex

PI reinforce : UBE, TaiFlex, SKC

Electromagnetic membrane : Fang Bang, Toyo, Sankei

2. Professional research and development department, with a production and quality management team with years of experience in flexible circuits fabrication.

3. Wide-range of production types as a PCB supplier: CTP, flexible PCB led strip, Biological recognition, automotive, and more…

4. Best cost solution deliverable from a variety of different design materials and expert evaluation of manufacturability in the end-design product.

5. Team of professionals available at you services 24/7

6. Strictly following the IPC standards in order to ensure the quality of the shipments.

7. Fast delivery time that provides the customers with marketing advantages.

We just highlighted some of the great services that the PCBONLINE provides. Make sure to visit their website to acquire a better understanding of PCB and how their set of skills will perfectly fit your project.