It’s interesting to explore what we can do with this tiny 8 pins; 8-bit microcontroller. The ATtiny13 is the smallest and cheapest Atmel AVR 8-bit microcontroller families but yet, it’s loaded with sophisticated peripherals such as two 8-bit PWM channels and 4 channels 10-bit ADC. Although the memory is quite small; 1 K flash, 64 SRAM and 64 EEPROM but this more the adequate for most PWM and ADC application, if you need more memory, bellow is the list of other Atmel AVR 8 pins microcontrollers which have compatible pins with ATtiny13 microcontroller.

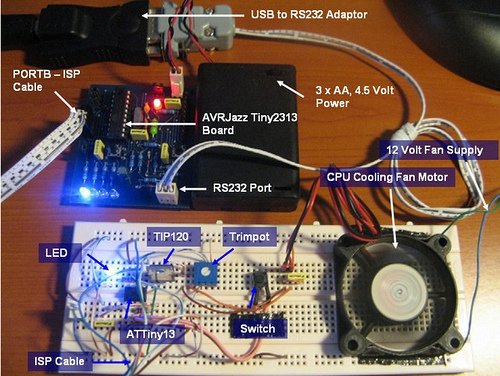

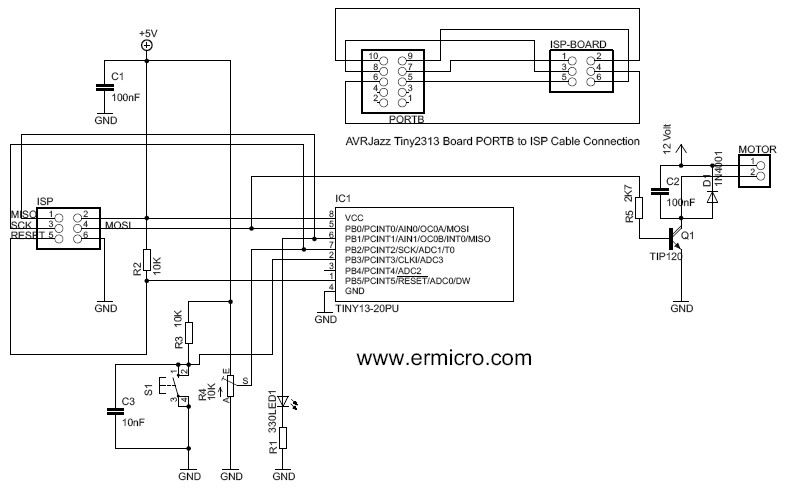

In order to demonstrate the ATtiny13 microcontroller capabilities using both PWM and ADC, I decided to use it for controlling the motor speed, after searching for the right motor for this project, finally I’ve found a microprocessor cooling fan from my old Intel Celeron computer; so I think this is a perfect motor for this project. By connecting it to the TIP120 Darlington pair transistor and to the ATtiny13 OC0A output we could easily controlling this fan speed using PWM, bellow is the complete schema for this project:

The 10K trimpot is used as an input for ADC which connected to the ADC1 input on the ATtiny13 (PIN 7) and to make it little bit more interesting I added the switch (S1) for switching the fan on/off and LED for the program life beacon, this LED will blink according to the PWM value passed to the fan, if the fan rotate faster the LED will blink slowly, but when the fan rotate slower the LED will blink faster. The fan speed is controlled by the trimpot which works as a voltage divider that supply the variable voltage to the ATtiny13 analog input.

The following is the list of hardware and software I use in this project:

- 3 Resistors: 2K7, 10K (2 pieces), 300 Ohm

- 1 Trimport: 10K

- 2 Capactors: 100nF, 1 capacitor: 10nF

- 1 Diode: 1N4001

- 1 LED

- AVR ATtiny13 microcontroller

- 1 TIP 120 Darlington pair transistor

- One 12 Volt DC motor

- AVRJazz Tiny2313 board as the programmer board from ermicro

- OvrOspII programmer software from Mike Henning

- Atmel AVR Studio 4 for the coding, compiling and debugging environment

The Tiny Code

To program the ATtiny13; this time I choose to use AVR’s assembler instead of C, because I just want to make sure that everything will feed into this tiny 1K flash boundary and just curiously how big this code will be; Ok let’s take a look in this assembler code bellow:

;********************************************************************* ; Program : t13pwm.asm ; Description : Tiny13 Fast PWM and ADC Fan Controller ; Last Updated : 15 December 2008 ; Author : RWB ; IDE/Compiler : Atmel AVR Studio 4.14 ; Programmer : AvrOspII v5.47 from Mike Henning ; : AVRJazz Tiny2313 Board ;********************************************************************* .include "tn13def.inc"

; The Tiny13 Default Frequency Clock .equ F_CPU = 9600000

.cseg

; Start on the flash ram's address 0 .org 0 main: ldi R24,RAMEND ; Initial Stack Pointer out SPL,R24 ; SP = RAMEND

; Initial I/O

ldi R16,0b00010011 ; Set PB0=Output, PB1=Output, PB2=Input, PB3=Input, PB4=Output

out DDRB,R16 ; DDRB=0x13

; Initial ADC

ldi R16,0b10000110

out ADCSRA,R16 ; Turn On the ADC, with prescale 64

ldi R16,0b00000000

out ADCSRB,R16 ; Free running mode

ldi R16,0b01100001

out ADMUX,R16 ; Internal Reference 1.1 Volt,Left Adjust, Channel: PB2 (ADC1)

ldi R16,0b00000100 ; Disable Digital Input on PB2

out DIDR0,R16

; Initial PWM

ldi R16,0b10000011

out TCCR0A,R16 ; Fast PWM Mode, Clear on OC0A

ldi R16,0b00000100

out TCCR0B,R16 ; Used fclk/256 prescale

; Initial the Button Flag and PORTB

ldi R17,0 ; Initial Button Flag

out PORTB,R17

lb_00: sbic PINB,PB3 ; if (PB3 == 0)

rjmp lb_20 ; else goto lb_20

ldi R19,5 ; Use delay for simple debounce

rcall delay_func

sbic PINB,PB3 ; if (PB3 == 0), read again

rjmp lb_20 ; else goto lb_20

cpi R17,1 ; Process if button pressed

brne lb_10 ; if (R17 != 1) goto lb_10

ldi R17,0 ; else R17=0

ldi R16,0 ; Disable PWM Clock

out TCCR0A,R16 ; TCCR0A = 0

out TCCR0B,R16 ; TCCR0B = 0

cbi PORTB,PB0 ; Turn off Motor

cbi PORTB,PB1 ; Turn off LED

rjmp lb_20

lb_10: ldi R17,1 ; R17=1

ldi R16,0b10000011

out TCCR0A,R16 ; Fast PWM Mode, Clear on OCR0A

ldi R16,0b00000100

out TCCR0B,R16 ; Used fclk/256 prescale

sbi PORTB,PB1 ; Turn on LED

lb_20: cpi R17,1 ; if (R17 != 1)

brne lb_40 ; goto lb_50

;

sbi ADCSRA,ADSC ; Start ADC conversion

lb_30: sbic ADCSRA,ADSC ; while (ADCSRA & (1<<ADSC))

rjmp lb_30

in R16,ADCH ; Read the result Ignore the last 2 bits in ADCL

out OCR0A,R16 ; OCR0A = R16

cbi PORTB,PB1 ; Turn off LED

mov R19,R16

rcall delay_func ; Call Delay Function Parameter R19

sbi PORTB,PB1 ; Turn on LED

lb_40: mov R19,R16

rcall delay_func ; Call Delay Function Parameter R19

rjmp lb_00

; Simple Delay Function

delay_func:

delay0: ldi R20,25 ; R20 = 25

delay1: ldi R21,255 ; R21 = 255

delay2: dec R21 ; Decrease R21

brne delay2 ; if (R20 != 0) goto delay2 label

dec R20 ; Decrease R20

brne delay1 ; if (R20 != 0) goto delay1 label

dec R19 ; Decrease R19

brne delay0 ; if (R19 != 0) goto delay0 label

ret ; Return to the caller

.exit

The first statement groups in the main area is to initial the stack, the stack use the microcontroller SRAM memory and we put the stack pointer to the end of 64 byte boundary (RAMED), the next statement groups is to initial the data direction register on the PORTB and make the direction as the following tables:

For more detail: Controlling DC motor with AVR ATtiny13 PWM and ADC Project