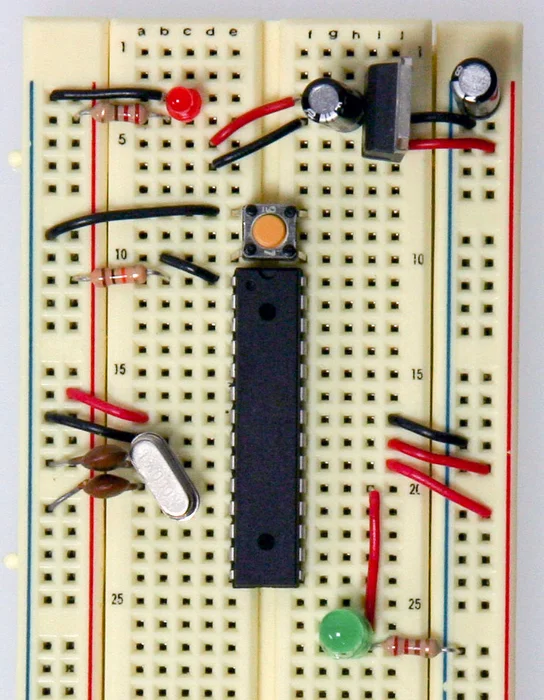

Step 1: Components and Where to Start

https://www.arduino.cc/en/Main/Standalone

where I’ve taken this picture, and where there is the list of all the components that you have to buy. Just the components that are showed in this picture.

( At the link, there are also others steps after this picture, that show you how to add the electronic part to program the ATmega328p, but because you can use yours Arduino board to program the Atmel, they are not important in this guide)

!!! PAY ATTENTION !!! : when you buy the ATmega328, it has to be a final “p” after the number like this:

ATmega328p-pu

This because there is another version of the component, without the final p,

that is less expensive, but it has some differences:

– the “p” stands for Pico Power, and it means that the microcontroller works at very low energy consumption

– but more important, the signature inside the microcontroller are different between the two versions, the one with final P and the one with no P, that makes an error during the programmation. This error could be bypassed, but in order to make all the things easier, buy the ATmega328p version.

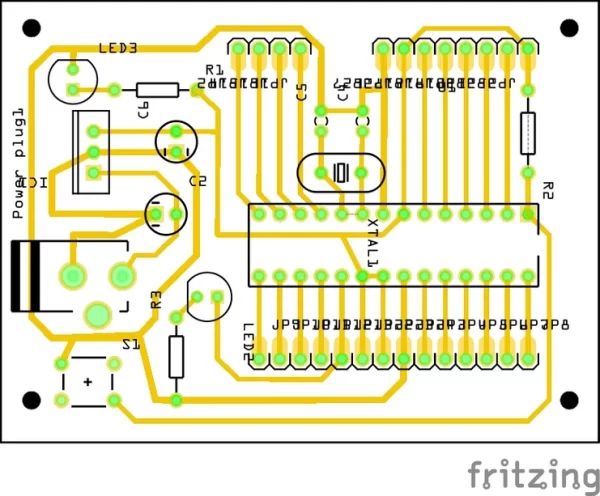

Step 2: The Schematic Draw

I’ve drawn the schematic with Frizzing, then I have printed on paper some prototypes to see if the circuit tracks were correct.

Here there is the pdf of the printed circuit board.

Attachments

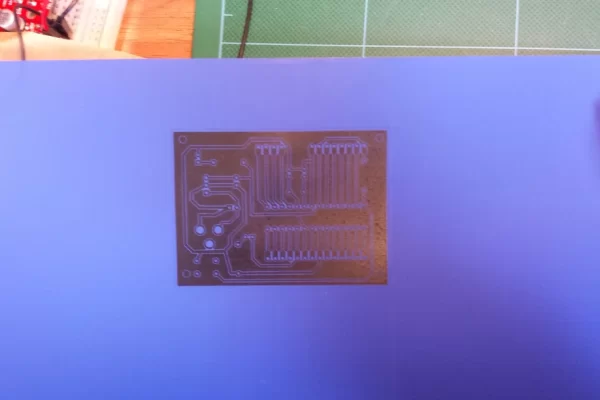

Step 3: Scissors, Alcool and Iron

Now the print: you need the PNP sheet (press-n-peel) and a LASER PRINTER (the ink printer can’t be used)

After printing the circuit on a PNP, you have to clean the copper with alcohol or kerosene distillate oil or a good degreasing as you prefer. You can also prepare the surface sanding it with sandpaper.

!!! PAY ATTENTION !!! : because it will be ironed onto the copper, that is the bottom surface, you DON’T HAVE TO FLIP the image I’ve posted in the previous step. Just print and put it on the copper.

The iron must not be too much hot: 1/2 or 3/4 of the scale will be enough, otherwise the circuit tracks will blend together over the copper surface. I say it for the experience.

Put a piece of fabric between the copper and the iron, push and make warm to the surface evenly for a minute or two. Then let cool the copper before touch it and then gently and carefully remove the blue sheet to reveal the blue drawn on the copper.

If there are some spots or interruption on the tracks, use a permanent pen to draw and repair the circuit.

You can see in the pictures the different color of my reparations. I think there were many because I haven’t cleaned properly the surface.

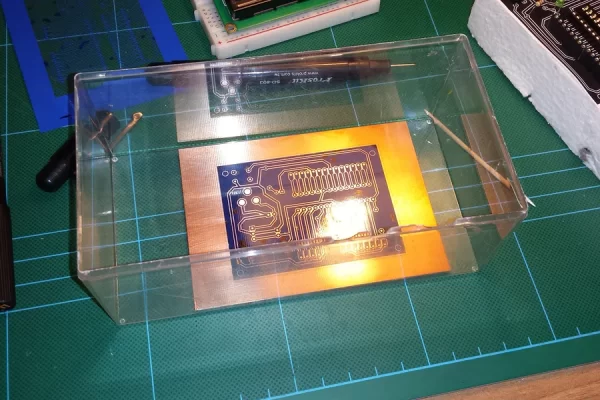

Step 4: A Bath Into Ferric Chloride (FeCl3)

Now the chemical part:

You must buy a bottle of Ferric Chloride (FeCl3) to remove the copper from the surface.

!!! PAY ATTENTION !!! : Use glasses and gloves When You use this substance, Because It’s corrosive to the skin, and watch out your clothes, Because if even a single drop goes on them, they will be permanently ruined.

Put it into a plastic recipient copper, not aluminum or other metal, and then put as much FeCl3 until to submerge the copper.

The chemical reaction ( FeCl3 + 3Cu -> 3CuCl + Fe(s) ) will be faster with agitation and making warmer the solution.

When the reaction will be completed, and all the copper will be gone, wash the fiberglass sheet with water.

Now you can remove the blue that covers the tracks with acetone, revealing the copper, as in the picture.